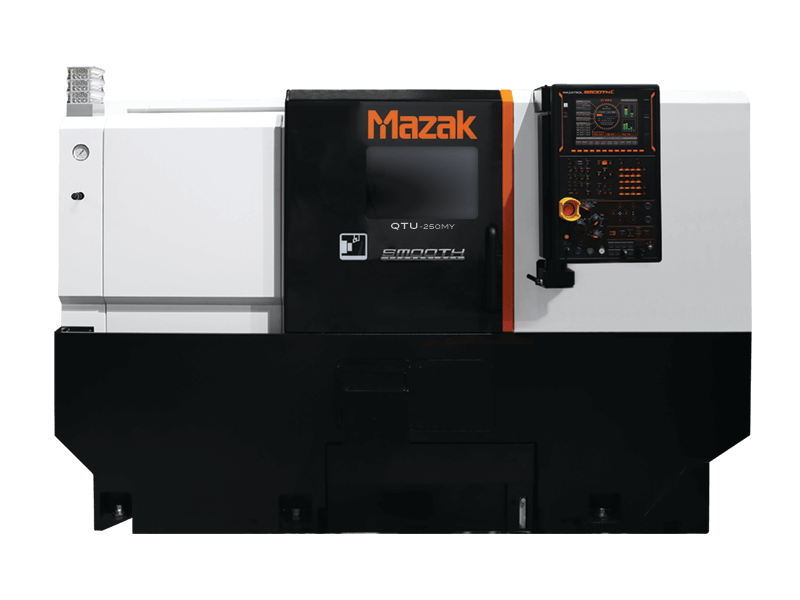

QTU-250MY

MACHINE DESCRIPTION:

With our simple but innovative QTU-250MY, shops never have to choose between Mazak quality and affordability when it comes to precision small parts production. This machine brings shops of all sizes advanced technology, unmatched productivity advantages and cost effectiveness.

Made in Kentucky, this versatile, small-footprint CNC Turning Center with Multi-Tasking capabilities brings maximum efficiency, reliability and value to those processing medical devices from aluminum, engine parts from cast iron, electronic enclosures from steel and much more. It features a main turning spindle, tool turret with rotary milling spindle and Y-axis off-centerline capabilities for Multi-Tasking part processing.

MACHINE CHARACTERISTICS:

- Spindle/motor design eliminates the need for belts and pulleys

- Main turning spindle delivers heavy-duty metal removal

- Integral-motor turret provides smooth, high-speed, high-accuracy digital indexing and expandability

- Rotary tool spindle performs milling, drilling and tapping operations

- Y-axis off-centerline drilling machining capability uses special high-gain servo-control turret/feed-axis motion for rigid, fast, precise positioning along with smooth axis acceleration/deceleration

- Fully programmable NC servo-driven tailstock introduces process automation

- Available with productive, flexible GR100 gantry loader system

Machine Specifications

| Specification | Bed Length - 500 mm / 19.685 in | |

|---|---|---|

| Capacity | Maximum Swing | 695 mm / 27.40 in |

| Maximum Machining Diameter | 340 mm / 13.500 in | |

| Maximum Bar Work Capacity | 51 mm / 2.0 in | |

| Maximum Machining Length | 532 mm / 21.034 in | |

| Main Spindle | Chuck Size | 203 mm / 8 in |

| Maximum Speed | 4500 rpm | |

| Motor Output (1 minute rating) | 15 kw / 20.0 hp | |

| Turret (Upper) | Number of Tools | 12 |

| Maximum Speed | 4500 rpm | |

| Motor Output (1 minute rating) | 6 kw / 7.4 hp | |

| Feed Axes | Travel (X Axis) | 215 mm / 8.50 in |

| Travel (Y Axis) | 100 mm / 4.00 in | |

| Travel (Z Axis) | 605 mm / 23.75 in | |

| Travel (W Axis) | 565 mm / 22.13 in | |