CNC Technology

Mazak set a precedent in CNC development with the introduction of our MAZATROL programming language in 1981. And, over the last three decades, we’ve continued to improve upon this programming language to easily put infinite part production capabilities under your control. From simple to the most complex parts, Mazak MAZATROL Smooth Controls give you complete control over your part programming.

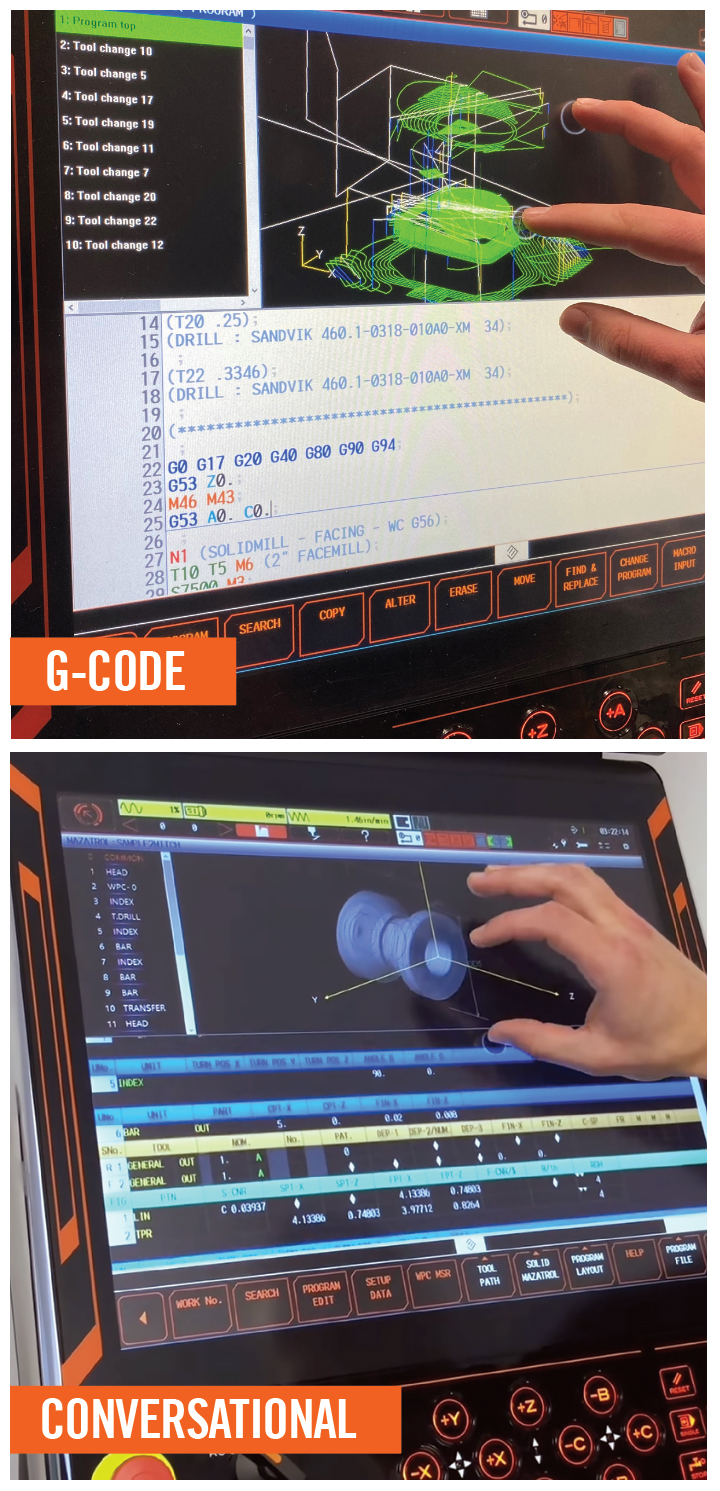

MAZATROL CONVERSATIONAL AND G-CODE PROGRAMMING

All Mazak MAZATROL Smooth Controls ship with Mazak’s ultra-high-speed machining software, which features both MAZATROL Conversational and G-Code EIA-ISO. In fact, the G-Code aspect of Mazak MAZATROL Smooth Controls can do things other CNCs cannot. Mazak MAZATROL Smooth Control users have the option to use either G-Code or conversational programming, or a combination thereof, making the control the most flexible and powerful in the industry.

All Mazak MAZATROL Smooth Controls ship with Mazak’s ultra-high-speed machining software, which features both MAZATROL Conversational and G-Code EIA-ISO. In fact, the G-Code aspect of Mazak MAZATROL Smooth Controls can do things other CNCs cannot. Mazak MAZATROL Smooth Control users have the option to use either G-Code or conversational programming, or a combination thereof, making the control the most flexible and powerful in the industry.

Advanced program functions of MAZATROL include:

- Tool Data Integration

- Adjustable Ultra Precision

- Quick EIA

- Quick MAZATROL

- Full-Machine Simulation

- Microsoft® Windows® Integration

- Part Offset Support

- Tool Offset Support

- Spare Tool Setup

- FANUC-Compatible G-code Support

- Easy G10 Data Change

- Flexible Macro Variables

Innovative CNC Technology Bridges the Skills Gap

For years, the growing gap between the number of manufacturing job opportunities and qualified candidates has alarmed manufacturers and policymakers alike. According to the 2018 Deloitte and The Manufacturing Institute Skills Gap and Future of Work Study, by 2028, this gap will have grown to 2.4 million positions, a massive number of unfilled jobs the authors estimate will cost the U.S. economy $2.5 trillion. Learn how MAZATROL conversational programming can help your shop bridge the skills gap.

THE ORIGINAL CONVERSATIONAL SOLUTION FOR PART PROGRAMMING

First introduced on the MAZATROL T-1 control equipped on the QUICK TURN 10", MAZATROL is a wizard-like programming mode that bypasses the use of G-code. This makes it possible for inexperienced operators to quickly and easily develop machining programs while out on the shop floor.

Operators begin the process answering conversationally displayed questions about the intended workpiece. These include type of material, O.D./I.D. dimensions and part lengths, among other queries. Then, according to the input data, the MAZATROL control automatically calculates intersection coordinates and tool index positioning in addition to optimized cutting conditions and machining processes.

As these questions are answered, the control constructs the program, then allows the machinist/programmer to visually check the tool path and verify the program. In the event of program flaws or missing information, the control will display an alert and the programmer must remedy the problem.

Maximize Performance and Ease of Use

MAZATROL CNC Controls

MAZATROL SmoothST

Fast, Easy Swiss-Style Machine Programming as Standard

Mazak developed its SmoothSt control for the company’s SYNCREX line of Swiss-style machines with the functions and capabilities shops have come to expect and built them into the control as standard. Like all the other controls in the full line of Mazak Smooth CNCs, SmoothSt also provides ease of use that dramatically reduces the learning curve for new operators.

The typically expected functions and capabilities of SmoothSt include setup and tool data screens, tool setup assist function, a multi-channel system for wait codes and synchronized movement commands, program check capability and the ability to verify the machine’s movement prior to pushing the cycle start button.

Functions include and capabilities include:

- SmoothSt Setup Data screen allows operators to enter information specific to the part to be machined, and the control automatically sets the cutting conditions for the cutoff/facing cycles used during tool setups.

- SmoothSt Tool Data screen displays an operator-selected tool group for easy tool data entry.

- Setup Assist makes for fast and easy tool setting for all the tools on a machine or just changing over certain tools needed from job to job.

- Manual Pulse Generator handle allows operators to execute/cycle through a full machining program operation to further verify a program and the machine’s movement to minimize the risk of crashes.

Faster, more powerful CNCs with advanced functions and capabilities as standard, like Mazak’s SmoothSt, play a key role in the reduction of Swiss-style machine idle time. The control optimizes programs and processes information faster, so shops can reduce machine idle time when running jobs with large lot sizes. Plus, the controls provide ease of use and substantially shorter setup times for even more time savings and increased production.

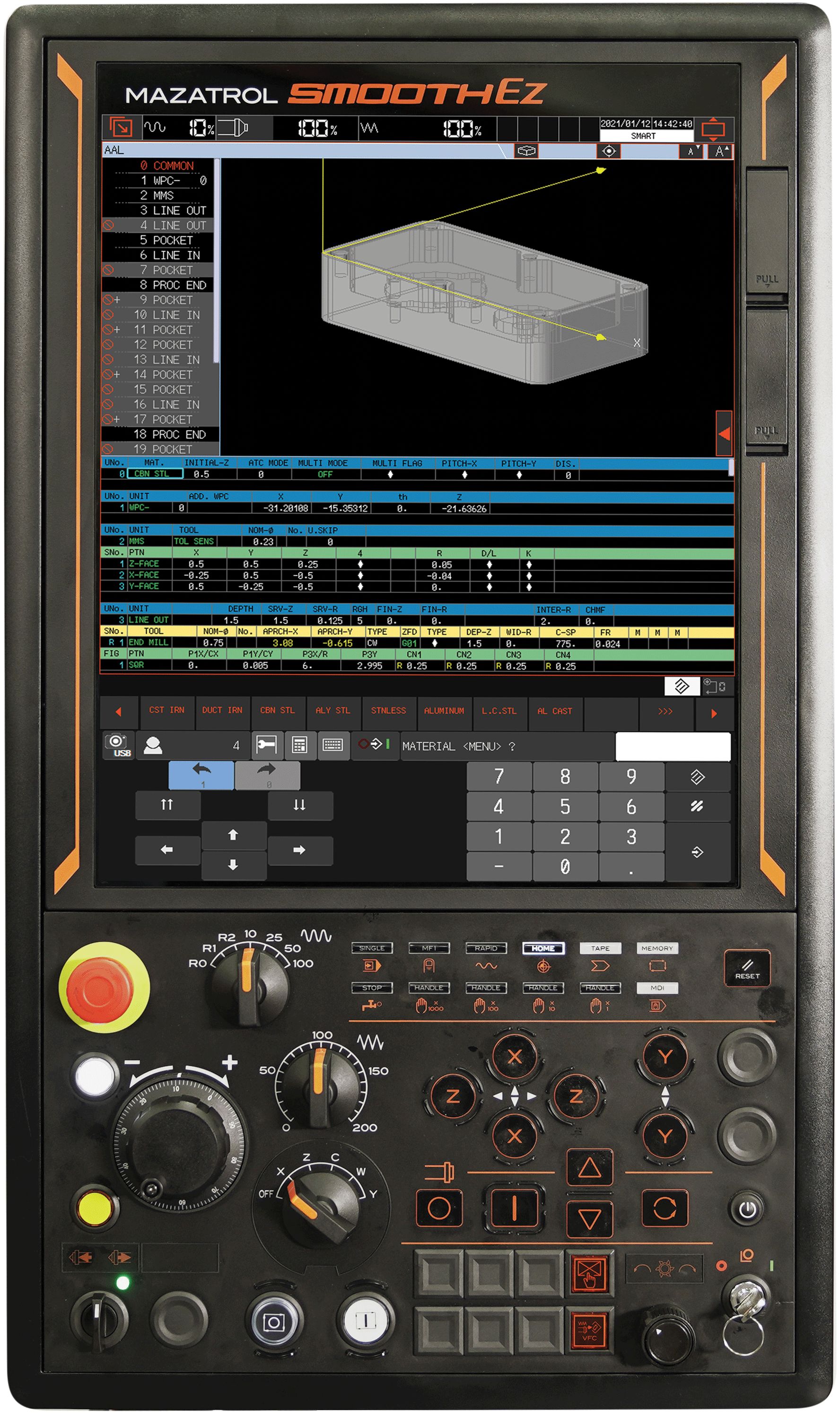

MAZATROL SmoothEz

EFFICIENT, USER FRIENDLY and ENHANCED WITH ADVANCED FEATURES

EFFICIENT, USER FRIENDLY and ENHANCED WITH ADVANCED FEATURES

The MAZATROL SmoothEz CNC packs productivity and enhanced features into a bright 15" capacitive touch-screen display with customizable screens and layouts, plus a full onscreen keyboard. The advanced user interface displays 60 programming lines at once to speed the use of both EIA/G-code and MAZATROL programming. The redesigned LAUNCHER screen uses the entire panel to ease screen selection and appears in icon form on every screen, with transition buttons to reach the home or a previous screen at a single touch. The control is responsive, efficient and easy to learn, even for new operators.

Functions Include:

- Solid MAZATROL utilizes 3D CAD data and AI-enhanced machining process selection to create optimized MAZATROL programs.

- Intelligent Thermal Shield ensures stable machining accuracy through machine-learning-enhanced heat displacement compensation.

- QUICK MAZATROL provides onscreen display of a 3D part model to simplify program creation and confirmation through the touch screen.

- MAZATROL TWINS links up with SMOOTH CAM Ai to simulate and analyze data for multiple machines and optimize machining parameters in real time.

- SMOOTH Project Manager allows users to synchronize the data associated with machining programs across an entire manufacturing facility, including virtual machines created with MAZATROL TWINS.

- SMOOTH Corner Control makes cutter path adjustments to help shorten cycle times.

- SMOOTH Machining Configuration (SMC) enables real-time process optimization with slider switches that allow operators to vary a wide range of cutting parameters.

For optimal ergonomics, a mounting arm enables the addition of a tablet that can be networked with auxiliary computers to operate CAD/CAM functions or SMOOTH Project Manager. An SD card slot enables the CNC to store up to 32GB of data.

MAZATROL SmoothEz5

EFFICIENT, USER FRIENDLY and ENHANCED WITH ADVANCED FEATURES

EFFICIENT, USER FRIENDLY and ENHANCED WITH ADVANCED FEATURES

Building on the functions and features of MAZATROL SmoothEz CNC machine control technology, Mazak now offers MAZATROL SmoothEz5 CNC that combines 5-axis capability with enhanced MAZATROL features, including:

- MAZATROL conversational and G-Code programming standard

- SMOOTH Machining Configurator (SMC) for real-time process optimization

- Intelligent Thermal Shield (ITS) to manage thermal stability

- Easy part program creation and confirmation with QUICK MAZATROL

- 15-inch capacitive touch screen display with full keyboard

- Intuitive, user-friendly interface for fast learning

MAZATROL SmoothAi

AI-POWERED PROGRAMMING FOR THE MOST COMPLEX PARTS

AI-POWERED PROGRAMMING FOR THE MOST COMPLEX PARTS

The next generation of MAZATROL Smooth CNC technology, the MAZATROL SmoothAi control and associated software packages deliver powerful digital enhancements that add efficiency and value throughout the machining process with the power of artificial intelligence (AI), machine learning and advanced data management technology.

The control incorporates a wide variety of advanced programming functions that allow it to offer complete ease of use and ensure high-speed, high-accuracy machining performance.

Functions Include:

- Solid MAZATROL utilizes 3D CAD data and AI-enhanced machining process selection to provide optimized MAZATROL programs.

- SMOOTH Ai Spindle leverages AI technology to optimize cutting conditions and surface finishes through automatic spindle vibration detection.

- Ai Thermal Shield ensures stable machining accuracy through machine-learning-enhanced heat displacement compensation.

- MAZATROL TWINS provides complete machine simulations to give programmers the ability to access virtual machines in their offices.

- SMOOTH CAM Ai gives operators the ability to simulate and analyze data for multiple machines and optimize machining parameters in real time.

- SMOOTH Robot Cell Controller simplifies programming and using robots with dedicated management software for high-mix/low-volume production.

- SMOOTH Project Manager allows users to synchronize the data associated with machining programs across an entire manufacturing facility, including to virtual machines created with MAZATROL TWINS.

- SMOOTH Machining Configuration (SMC) enables real-time process optimization with slider switches that allow operators to vary a wide range of cutting parameters.

- SMC Plus serves as an optional software module that assists operators in correcting tool contact points in EIA programs using 3D part models for improved accuracy and part quality.

Ergonomics also play an important role in the functionality of this control. A large 19" display presents all of the critical machine data on a single page, while the tilt control panel allows for optimal positioning based on operator height. For additional functionality, an optional second screen can provide data from SMOOTH Ai Spindle, SMOOTH PMC and SMOOTH RCC. An intuitive multi-touch screen enables fast and smooth programming operations. An SD card allows the CNC to store up to 32GB of data.

MAZATROL SmoothX

Revolutionary Programming for Highly Complex Part Production

Revolutionary Programming for Highly Complex Part Production

As the fastest, most progressive CNC on the market, the MAZATROL SmoothX brings extreme productivity advantages to the most demanding machining operations. It ensures the shortest possible machining cycle times, especially in fine increment programs for simultaneous 5-axis operations and free-form die-mold machining.

The control incorporates a wide variety of advanced programming functions that allow it to offer complete ease of use and ensure high-speed, high-accuracy machining performance.

Functions Include:

- Super High-Speed Mode helps provide maximum interpolation capabilities.

- High Gain Feed Forward Control boosts machining speed and accuracy.

- Fast Rotary Axis Speeds optimize gear skiving and rotary axis threading.

- Variable Acceleration Control calculates optimal acceleration for a combination of axes.

- Intelligent Pocket Milling engages a high-efficiency toolpath when milling part cavities.

- Smooth Corner Control makes cutter path adjustments to help shorten cycle times.

- Orbit Machining allows a machining center with a C-axis to turn complex features on parts.

- Position Controlled Hobbing provides fast, convenient hobbing and skiving operations.

- Real Time Tuning ensures optimal machining balance as workpiece weight changes.

Ergonomics also play an important role in the functionality of this control. A large 19" display presents all of the critical machine data on a single page, while the tilt control panel allows for optimal positioning based on operator height. An intuitive multi-touch screen enables fast and smooth programming operations. An SD card allows the CNC to store up to 32GB of data.

MAZATROL SmoothG

Highly Optimized Programming for Complex Part Production

Highly Optimized Programming for Complex Part Production

The MAZATROL SmoothG makes it easy to generate programs for processing complex parts through off-centerline machining as well as angled drilling, milling and tapping.

The control incorporates a wide variety of advanced programming functions that allow it to offer complete ease of use and ensure high-speed, high-accuracy machining performance.

Functions Include:

- High Gain Feed Forward Control boosts machining speed and accuracy.

- Fast Rotary Axis Speeds optimize gear skiving and rotary axis threading.

- Variable Acceleration Control calculates optimal acceleration for a combination of axes.

- Intelligent Pocket Milling engages a high-efficiency toolpath when milling part cavities.

- Smooth Corner Control makes cutter path adjustments to help shorten cycle times.

- Orbit Machining allows a machining center with a C-axis to turn complex features on parts.

- Position Controlled Hobbing provides fast, convenient hobbing and skiving operations.

- Real Time Tuning ensures optimal machining balance as workpiece weight changes.

Ergonomics also play an important role in the functionality of this control. A large 19" display presents all of the critical machine data on a single page, while the tilt control panel allows for optimal positioning based on operator height. An intuitive multi-touch screen enables fast and smooth programming operations. An SD card allows the CNC to store up to 32GB of data.

MAZATROL SmoothC

Advanced Programming for Complex Part Production

Advanced Programming for Complex Part Production

Mazak’s latest MAZATROL SmoothC technology is simple but innovative. It has both new and improved features that enhance cutting capabilities. The MAZATROL SmoothC makes it easy for operators to generate programs for basic turning, milling, drilling and tapping operations.

The control incorporates a wide variety of advanced programming functions that allow it to offer complete ease of use and ensure high-speed, high-accuracy machining performance.

Functions Include:

- Rapid Overlap uses arcing motion between programmed stopping points to shorten cycle times.

- Smooth CAM RS simulates SMOOTH controls on a remote PC.

- High Gain Feed Forward Control boosts machining speed and accuracy.

- Variable Acceleration Control calculates optimal acceleration for a combination of axes.

- Intelligent Pocket Milling engages a high-efficiency toolpath when milling part cavities.

- Smooth Corner Control makes cutter path adjustments to help shorten cycle times.

- Orbit Machining allows a machining center with a C-axis to turn complex features on parts.

- Position Controlled Hobbing provides fast, convenient hobbing and skiving operations.

- Real Time Tuning ensures optimal machining balance as workpiece weight changes.

MATRIX 2

Advanced Programming for highly complex workpiece geometries

Advanced Programming for highly complex workpiece geometries

The MATRIX 2 CNC makes it easy to generate programs for multi-tasking and simultaneous 5-axis operations as well as automated processes. It features advanced hardware and software functions that ensure fast processing speeds, excellent cornering and superior surface finish in highly complex part production. The CNC accommodates up to nine axes and stores up to 20GB of program data. It also features an extended card for connection to field networks.

MATRIX NEXUS 2

Optimized Programming for Complex Workpiece Geometries

Optimized Programming for Complex Workpiece Geometries

The MATRIX NEXUS 2 CNC makes it easy to generate programs for angled drilling, milling or tapping operations. It features advanced hardware and software functions that help ensure high productivity and performance in complex part production. The CNC can simultaneously control up to three axes, handle the continuous control of second spindles and save up to 20GB of program data.