Transform Your Welding Capabilities

For industries ranging from energy production to electronics and shipbuilding to aerospace, advanced welding technology has been key to the development of the next generation of spacefaring vessels, natural gas pipelines and semiconductor fabrication equipment. And for these industries and beyond, the next generation of welding has arrived: Friction Stir Welding (FSW), brought to you by your partners at Mazak MegaStir.

A Better Weld

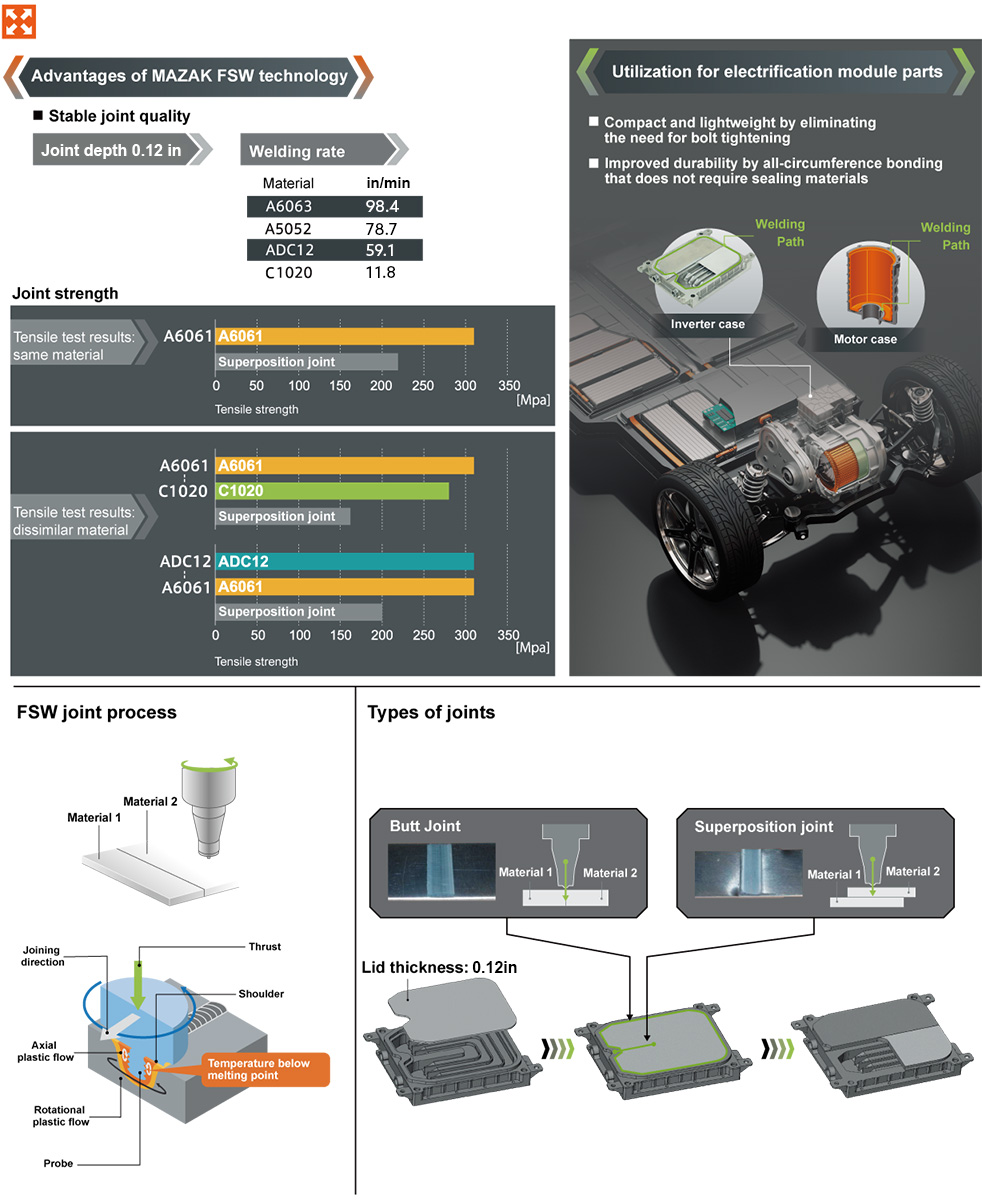

A solid-state joining process that uses frictional heat and forging pressure, FSW creates full-penetration, defect-free welded joints with greater strength than conventional welding methods. The process utilizes a non-consumable tool to join two metal plates without melting the workpiece. Commonly considered a forging process, FSW is well-suited for joining alloys with low melting points, including aluminum, copper and brass, as well as handling high-temperature welding in steels and nickel-based alloys.

Partnering for Your Productivity

Founded in 2001, MegaStir has been a pioneering force in the development of Friction Stir Welding (FSW), creating proprietary technologies aimed at combining un-joinable materials, including steel and high-temperature alloys. Today, Mazak MegaStir applies FSW technology within Mazak’s HYBRID Multi-Tasking family of machines, such as the VTC-300C FSW.

Case Study for the Automotive Industry

Case Study for the Semiconductor Industry

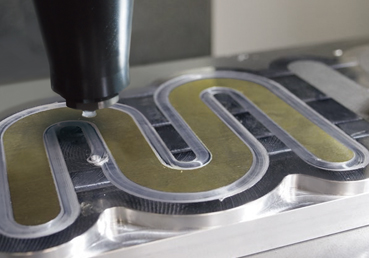

Process from machining to FSW

Application examples

Ready to find out how FSW technology can transform your shop with expanded welding capabilities? Visit the Mazak MegaStir headquarters in Provo, Utah to see the process for yourself or browse the company’s website at MegaStir.com.

Learn More About Mazak MegaStir