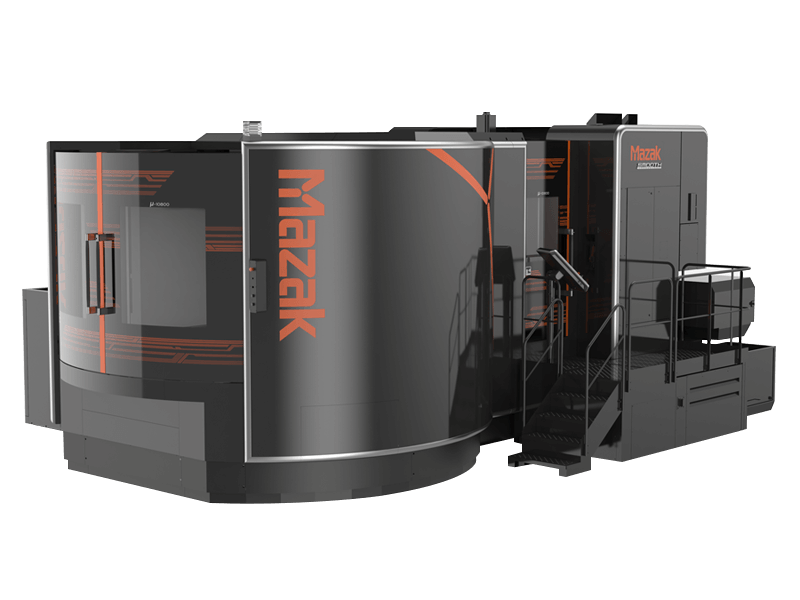

HCN µ-10800

MACHINE DESCRIPTION:

The ultra-accurate HCN µ-10800 Horizontal Machining Center enhances performance for machining parts that demand extraordinarily tight tolerances. With technologies such as linear motion guides, µ Series machines create finished workpieces with accuracies that rival those of a jig-bore. DONE IN ONE® capabilities maximize productivity, reduce production lead times, improve accuracy and lower operating expenses. These machines are the best choice for high-speed, high-power machining in a broad spectrum of lot sizes.

MACHINE CHARACTERISTICS:

- Complete roughing and finishing operations with DONE IN ONE capabilities

- Ultra-high accuracy for tight tolerance demands

- Positioning accuracy greater than 0.00013" with repeatability greater than 0.00008"

- Extremely fast rapid traverse speeds

- High-rigidity machine construction makes highly accurate finished parts

- PALLETECH ready for lights-out production

Machine Specifications

| Specification | Values | |

|---|---|---|

| Capacity | Pallet Size | 1000 mm / 39.370 in |

| Spindle | Spindle Taper | No. 50 |

| Maximum Speed | 10000 rpm | |

| Motor Output (30 minute rating) | 37 kw / 50.0 hp | |

| Magazine | Number of Tools | 80 |

| Feed Axes | Travel (X Axis) | 1700 mm / 66.93 in |

| Travel (Y Axis) | 1400 mm / 55.12 in | |

| Travel (Z Axis) | 1525 mm / 60.03 in | |