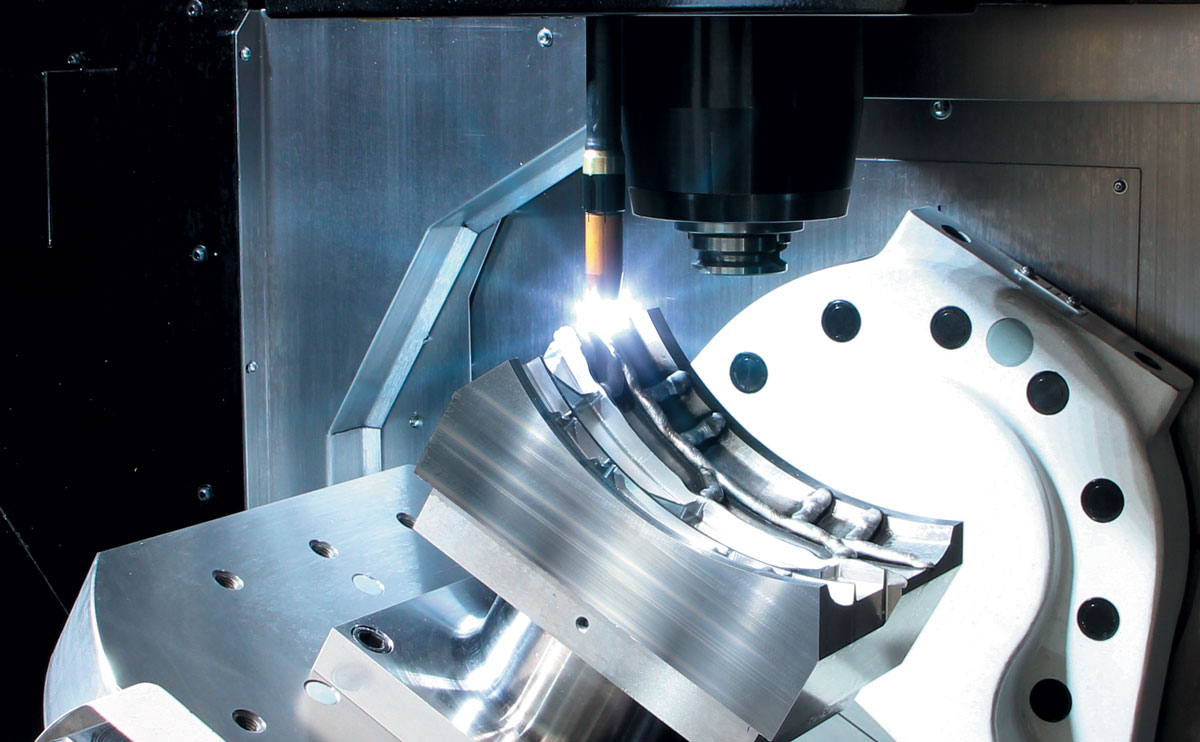

ADDITIVE MANUFACTURING (AM) offers fast, innovative ways to build parts in addition to subtractive processes.

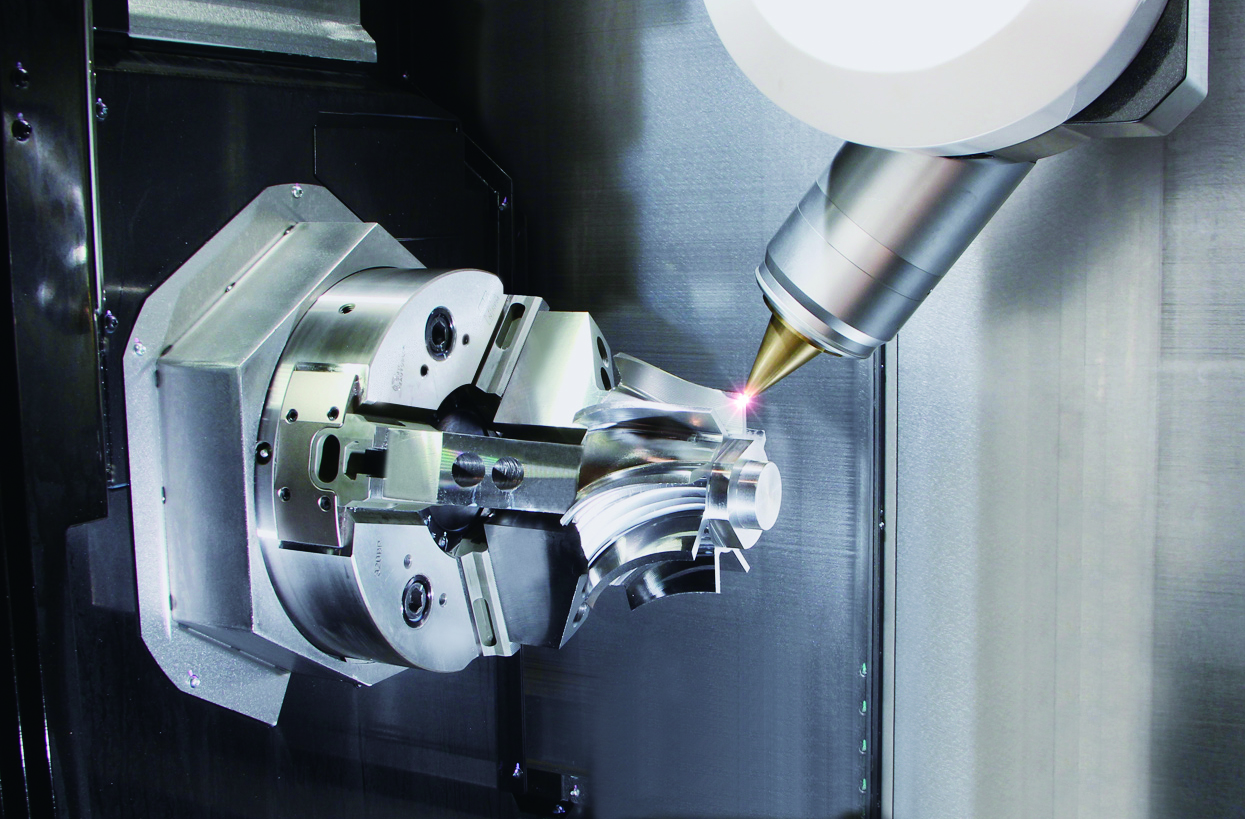

Laser Metal Deposition

Reduce scrap and speed the creation of accurate part features with laser power in a streamlined workflow, all on a machine that can finish and semi-finish additive production. To produce high-strength joints among different types of metals, this high-speed additive manufacturing process uses a high-powered laser to melt both base material and metal powder.