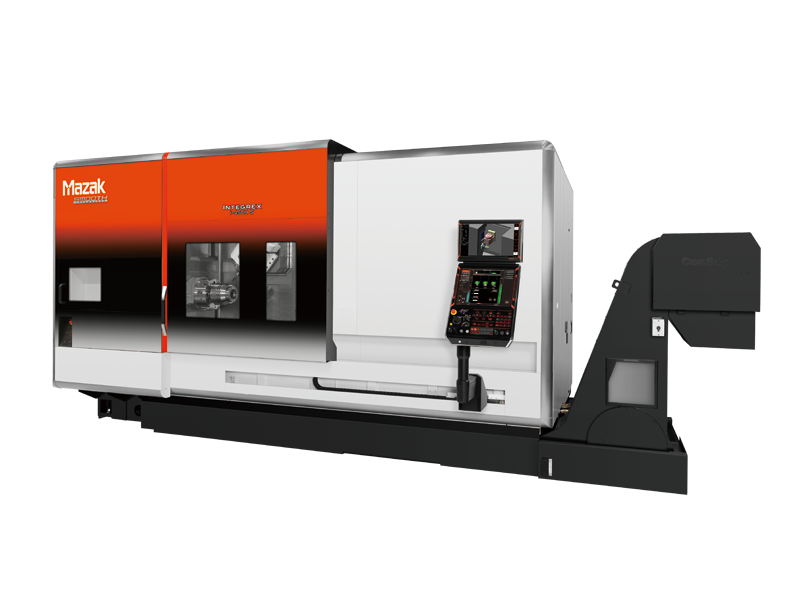

INTEGREX i-350H S

Photo of INTEGREX i-200H ST with optional equipment

MACHINE DESCRIPTION:

The INTEGREX i-350H S Multi-Tasking Center features a second turning spindle and delivers the highest level of single-setup part-production versatility of a high-powered turning center and full-function machining center combined. This machine configuration features a second turning spindle (S) for DONE IN ONE® machining, minimizing fixtures, tools, handling and non-cut time.

The machine enclosure and tool magazine accommodate a comprehensive range of automation technologies, including gantry loaders, bar feeders, and articulating robots. And thanks to the power of its MAZATROL SmoothAi CNC, the INTEGREX i-350H S offers standard specialized operations such as crank shaft inclined drilling or gear skiving.

MILLING SPINDLE SPECIFICATIONS

Meet your part-production needs with a range of spindles.

| Speed | Standard | High-speed* |

|---|---|---|

| 12000 rpm | 20000 rpm | |

| Output (40% ED) |

32 hp (24 kW) | 32 hp (24 kW) |

| Max. torque (40% ED) |

124 N⋅m | 124 N⋅m |

* option

Automation

Bar feeder

With a bar feeder and optional scheduling software, shops can easily manage both high-mix/low-volume production and high-volume production.

INTEGREX i-450H ST shown

TURN ASSIST (TA)

Thanks to easy-to-use software, the RoboJob Turn Assist robot system does not require complicated teaching routines to achieve smooth, efficient movement for loading and unloading parts.

INTEGREX i-450H ST shown

GANTRY LOADER SYSTEM

The optional Gantry Loader (GL) features a compact design that lowers machine height and reduces loading/unloading time. Install the part conveyor on either the right or left side of the machine and even integrate it with multiple machines.

INTEGREX i-200H ST shown

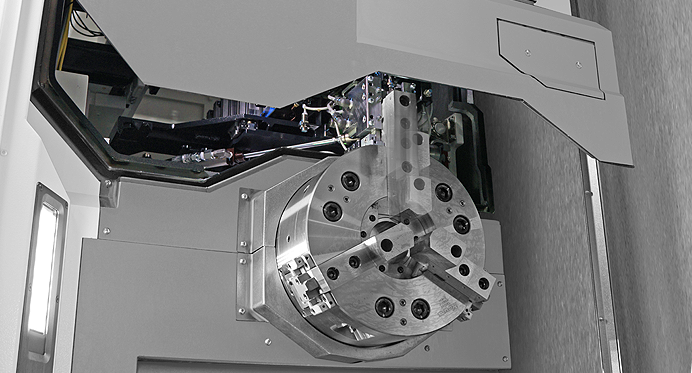

AUTO JAW CHANGER

Automatically change out jaws from 10-jaw stockers located on each spindle via program commands.

Caractéristiques de la machine

| Spécification | Bed Longueur - 1500U mm | Bed Longueur - 2500U mm | |

|---|---|---|---|

| Capacité | Balançoire maximum | 670 mm / 26.38 in | 670 mm / 26.38 in |

| Diamètre d'usinage maximum | 670 mm / 26.380 in | 670 mm / 26.380 in | |

| Capacité Bar de travail maximale | 80 mm / 3.2 in | 80 mm / 3.2 in | |

| Usinage Longueur maximale | 1519 mm / 59.800 in | 2500 mm / 98.430 in | |

| Broche principale | Chuck Taille | 10 in | 10 in |

| Vitesse de pointe | 4000 rpm | 4000 rpm | |

| Deuxième broche | Chuck Taille | 10 in | 10 in |

| Vitesse de pointe | 4000 rpm | 4000 rpm | |

| Fraisage de la broche | Axe B Voyage | 240° | 240° |

| Capacité du chargeur | 38 | 38 | |

| Vitesse de pointe | 12000 rpm | 12000 rpm | |

| Nourrir axes | Voyage (axe X) | 695 mm / 27.36 in | 695 mm / 27.36 in |

| Voyage (axe Y) | 300 mm / 11.81 in | 300 mm / 11.81 in | |

| Voyage (axe Z) | 1585 mm / 62.40 in | 2566 mm / 101.02 in | |