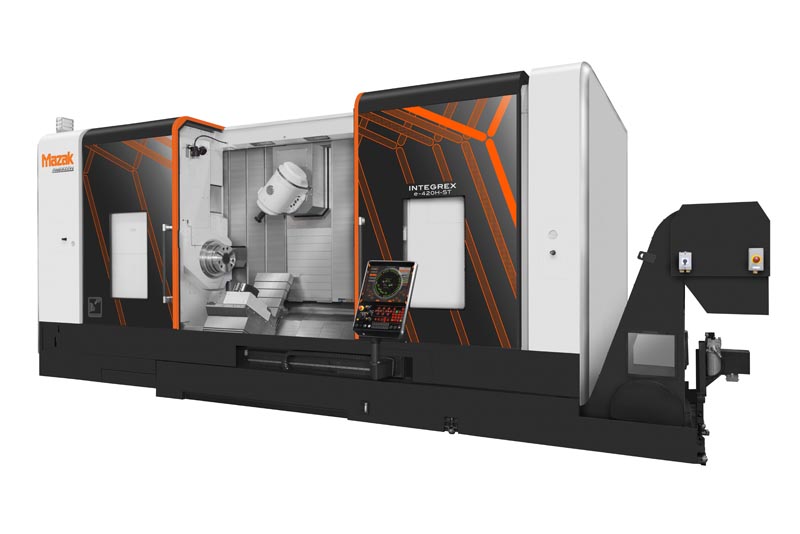

Mazak’s new INTEGREX e-420H-ST features a lower turret with large 16.5" Y-axis stroke. The added turret works with the machine’s twin turning spindles and main milling spindle for the ultimate in 5-axis DONE IN ONE part processing.

Mazak’s new INTEGREX e-420H-ST features a lower turret with large 16.5" Y-axis stroke. The added turret works with the machine’s twin turning spindles and main milling spindle for the ultimate in 5-axis DONE IN ONE part processing.

The INTEGREX e-420H-ST sports the new MAZATROL SmoothX CNC that is a key element – along with new machine hardware and servo systems – of Mazak’s SMOOTH TECHNOLOGY. As a dramatic evolution in the advancement of machine tools, SMOOTH TECHNOLOGY is a complete process-performance platform that spans the entire part-production landscape from programming and setup to metal removal operations and automation to monitoring and data collection/transfer.

The machine’s two opposing spindles have a 40-hp output, maximum speeds of 4,000 rpm and C-axis control. Additionally, a strong 30-hp, 12,000-rpm integral motor milling spindle with a CAT 40 or CAPTO C6 interface rotates 240 degrees in the B-axis to provide simultaneous 5-axis and high-feedrate milling operations.

Tool storage capacities of 40, 80 or 120 tools ensure continuous machining as well as offer versatility in the shapes and sizes of tools that can be stored to further support Multi-Tasking part processing operations. Plus, the machine’s maximum swing of 26.4" along with a bed length of 80" accommodates longer workpieces.

Axis travels on the INTEGREX e-420H-ST are 33.27" in X, 16.54" in Y and 82.2" in Z. They incorporate Mazak’s MX Hybrid Roller Guide System that provides levels of durability and reliability, resulting in long-term accuracy. The innovative way system increases vibration dampening, extends tool life, handles higher load capacities and eliminates tramp oil in the coolant by utilizing a greener grease-based lubrication system.