Mazak Blog

Don’t Take Unnecessary Risks with Your Machine Tool Spindles

For many shops, the reason they forego using the machine tool OEM and instead go with an outside service provider for spindle repairs is often price. While these shops hope to save money, they run the risk of spindle repairs that are okay but, in reality, can actually hinder machines tools from performing at their highest levels. When opting for an outside repair service provider, the risk often far outweighs the cost savings.

Read MoreConsider The OEM Your Machine Tool Service and Support Specialist

When it comes to service and support from third-party suppliers, the phrase “jack of all trades and master of none” sums up the situation in some instances. While many third-party machine service and repair companies are quite capable, they typically work on a myriad of machine types and brands and aren’t always as well versed on the nuances of a particular model/brand as are the machine’s OEM.

Read MoreAre You Ready to Compete in 2024?

In 2024, economic factors will continue to challenge manufacturers. The manufacturing sector will continue to experience a mild recession as the consumer-driven part of the economy quickly slows. With 10,000 baby boomer generation employees predicted to leave the workforce per day, according to a report by ITR Economics, the labor shortage will also persist in the coming year. On top of all this, wage rates will climb along with interest rates and energy costs.

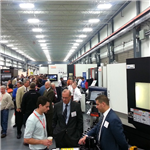

Read MoreMazak DISCOVER 2023 Highlights Power, Productivity and Precision

Over 2,000 visitors from 46 U.S. states and seven countries joined us for DISCOVER 2023 – and the largest privately held manufacturing event in North America held excitement in store for every attendee. Our latest innovations demonstrated technologies to suit shops of all sizes and workflows of all types. Along with 29 Mazak machine tools to build success, we hosted a long list of speakers with insights and advice gleaned from industry expertise. The entire show – including the ever-popular family day – made Mazak the place to be from October 9-13, 2023.

Read MoreMazak SYNCREX Takes Swiss-style Turning to New Levels

Mazak’s Kentucky-built SYNCREX Series – the company’s entry into the Swiss-style turning machine market – provides shops a feature-rich machine platform that meets the growing demand for both low-mix/high-volume production and high-mix/low-volume production. While they are especially adept at machining complex, unconventional parts, the machines in the series can also run any part that could be turned on a standard lathe.

Read MoreAutomation is the Rule Not the Exception

Whether or not shops want to admit it, automation is the path forward for manufacturing. As skilled labor shortages continue to plague our industry and consumer demand surges, automation is necessary to increase the output of existing workforces and expanding production capacity to meet customer needs. Additionally , automation ensures process consistency, improves quality, can enhance safety, helps lower overall costs and reduces the risk of scrap.

Read MoreNextGen Cars Mean Next-Generation Machining Strategy for Team Penske

The establishment of NextGen cars in the NASCAR Cup Series has had a profound impact at Team Penske. As a result of the rules and requirements surrounding those cars, the team went from building all of its own cars on site and manufacturing the majority of the components for those cars to basically purchasing off-the-shelf cars.

Read MoreG-Code and Conversational – MAZATROL Does it All

Industrial machining computer numerical control (CNC) programming language has evolved through many iterations since its inception in the 1950s. Standardized in the early 1960s by the Electronic Industries Alliance as RS-247-D and now known as EIA/ISO machine programming – or G-code – it has become the foundational and most widely used protocol for precision control of vertical and horizontal machining centers, lathes and additive 3D printers, detailing every movement and action necessary to produce parts ranging from the simple to the unfathomably complex.

Read MoreEffective Countermeasures for Machine Tool Supply Chain Disruptions

Every business and every consumer can provide their own unique examples of product delivery delays and cancellations resulting from pandemic-bred supply chain interruptions. As a provider of premium machine tools worldwide, Mazak is no exception. In the last two years, the time required to get machine tool parts from Asia to the U.S. has essentially doubled, and the delays do not end when the cargo arrives in this country.

Read MoreCustomer Challenge: Double Enveloping Worm Threading on a Multi-Tasking Machine

Recently, a customer challenged Mazak to develop a programming and machining solution for producing a variety of Double Enveloping Worm Threads. The customer not only wanted the solution to be user-friendly and provide the ability to adjust the thread geometry based on inspection data (such as a roll test with a Master Worm Gear) but to also allow for the use of common off-the-shelf cutters.

Recently, a customer challenged Mazak to develop a programming and machining solution for producing a variety of Double Enveloping Worm Threads. The customer not only wanted the solution to be user-friendly and provide the ability to adjust the thread geometry based on inspection data (such as a roll test with a Master Worm Gear) but to also allow for the use of common off-the-shelf cutters.

Chip Manufacturer Gives the Inside Scoop on Vacuum Chamber Production

Mazak sat down with one of the major manufacturers in the semiconductor chip industry to discuss the ongoing chip shortage and the critical role that vacuum chamber machining plays in helping to meet surging demand. According to our industry insider, the huge demand for new vacuum processing chambers reflects the need to build new systems to produce chips as well as to replace worn out existing chambers.

Mazak sat down with one of the major manufacturers in the semiconductor chip industry to discuss the ongoing chip shortage and the critical role that vacuum chamber machining plays in helping to meet surging demand. According to our industry insider, the huge demand for new vacuum processing chambers reflects the need to build new systems to produce chips as well as to replace worn out existing chambers.

Real Improvement in Medical Manufacturing Requires Real Machine Data

The integration or connecting of CAD/CAM software to a machine tool can increase the confidence factor when it comes to machining your complex medical parts. When these systems are paired together with Mazak’s advanced SMOOTH control technology, you not only gain valuable real time data at the machine but also the ability to generate more accurate part program simulations, which in turn, increase your shop’s odds tremendously of producing a good first part, thus minimizing prove out time.

The integration or connecting of CAD/CAM software to a machine tool can increase the confidence factor when it comes to machining your complex medical parts. When these systems are paired together with Mazak’s advanced SMOOTH control technology, you not only gain valuable real time data at the machine but also the ability to generate more accurate part program simulations, which in turn, increase your shop’s odds tremendously of producing a good first part, thus minimizing prove out time.

New Multi-Tasking Series Made for Medical

Our redesigned INTEGREX i-H Series of Multi-Tasking machines takes optimized machining and easy automation to new heights. For medical manufacturers in particular, these machines meet and exceed the competitive need for precision and superior surface finishes on demanding parts that have no margin for error.

Our redesigned INTEGREX i-H Series of Multi-Tasking machines takes optimized machining and easy automation to new heights. For medical manufacturers in particular, these machines meet and exceed the competitive need for precision and superior surface finishes on demanding parts that have no margin for error.

Real Shops Offer Real Solutions to Today’s Business Challenges

No one knows the trials and tribulations of the manufacturing industry better than those who own or manage job shops within that sector. During our DISCOVER 2021 event, we hosted the Job Shop/Profit Shop panel discussion to address some of the current challenges that today’s small to medium-sized shops face and gain insight into how these enduring shops ensure their continued success.

No one knows the trials and tribulations of the manufacturing industry better than those who own or manage job shops within that sector. During our DISCOVER 2021 event, we hosted the Job Shop/Profit Shop panel discussion to address some of the current challenges that today’s small to medium-sized shops face and gain insight into how these enduring shops ensure their continued success.

Mazak DISCOVER 2021 Proves an Event Like No Other

We welcomed more than 1,500 people at this year’s Mazak DISCOVER 2021 event, once again staking our claim to hosting the largest privately held manufacturing event in North America. Like its predecessors, DISCOVER 2021 was nothing short of amazing and gave attendees plenty of excitement, along with a host of new ideas and technologies to keep their shops competitive and successful.

We welcomed more than 1,500 people at this year’s Mazak DISCOVER 2021 event, once again staking our claim to hosting the largest privately held manufacturing event in North America. Like its predecessors, DISCOVER 2021 was nothing short of amazing and gave attendees plenty of excitement, along with a host of new ideas and technologies to keep their shops competitive and successful.

MPower Complete Customer Care Puts Customers Ahead

At Mazak, customer satisfaction and uptime come first, and MPower takes care of every aspect of support to make your life easier. With one point of contact for everything you need, MPower adds enormous value throughout the life of each machine tool. Streamline the parts-ordering process, avoid costly service calls, get the right parts without delays and teach your team the latest techniques without taking time away from production

At Mazak, customer satisfaction and uptime come first, and MPower takes care of every aspect of support to make your life easier. With one point of contact for everything you need, MPower adds enormous value throughout the life of each machine tool. Streamline the parts-ordering process, avoid costly service calls, get the right parts without delays and teach your team the latest techniques without taking time away from production

7 Reasons to Make DISCOVER 2021 Your Must-See Event This Year

You're on the lookout for every advantage that can propel your shop past your competition. At Mazak, we offer a long list of great solutions to help you do just that – and we're going to share that list with you as we Move Manufacturing Forward at DISCOVER 2021, October 25-29 at our North American Headquarters Campus in Florence, Kentucky.

You're on the lookout for every advantage that can propel your shop past your competition. At Mazak, we offer a long list of great solutions to help you do just that – and we're going to share that list with you as we Move Manufacturing Forward at DISCOVER 2021, October 25-29 at our North American Headquarters Campus in Florence, Kentucky.

Why Should You Care About MPower

Mazak’s MPower is the industry’s most comprehensive customer service and support program. That's the obvious reason it matters to every Mazak customer. But to truly understand MPower's value requires delving into all that the program offers.

Mazak’s MPower is the industry’s most comprehensive customer service and support program. That's the obvious reason it matters to every Mazak customer. But to truly understand MPower's value requires delving into all that the program offers.

Why a Probe is the First Tool You Should Load in Your Machine’s Spindle

On-machine probing is particularly critical for Mazak customer Jasper Engines and Transmissions. The shop’s Mazak HCN 6800 Horizontal Machining Center processes families of engine cylinder heads, and the parts can look similar, but involve very different dimensions. For this reason, the first tool Jasper Engines and Transmissions runs is a probe that confirms a part is loaded, identifies it and conveys that information to the machine’s control, which in turn selects and runs the correct program for that particular part – virtually eliminating any risk of error.

On-machine probing is particularly critical for Mazak customer Jasper Engines and Transmissions. The shop’s Mazak HCN 6800 Horizontal Machining Center processes families of engine cylinder heads, and the parts can look similar, but involve very different dimensions. For this reason, the first tool Jasper Engines and Transmissions runs is a probe that confirms a part is loaded, identifies it and conveys that information to the machine’s control, which in turn selects and runs the correct program for that particular part – virtually eliminating any risk of error.

Mazak NEO: Making the Best Even Better

Much as the model names Porsche® 911® and Jeep® Grand Cherokee® are icons of the automotive world, so are Mazak’s HCN Series of Horizontal Machining Centers and its VARIAXIS Series of Vertical Machining Centers among manufacturers. All these iconic brand names share a reputation for performance, quality and reliability achieved through continuous improvement and redesign with the end user’s needs in mind.

Much as the model names Porsche® 911® and Jeep® Grand Cherokee® are icons of the automotive world, so are Mazak’s HCN Series of Horizontal Machining Centers and its VARIAXIS Series of Vertical Machining Centers among manufacturers. All these iconic brand names share a reputation for performance, quality and reliability achieved through continuous improvement and redesign with the end user’s needs in mind.

What to Expect From a Truly Effective Personal Service and Support Portal

The goal of any online personal service and support portal is to enhance the customer experience and add value. Unfortunately, as many manufacturing equipment suppliers rush to jump on the me-too portal bandwagon, the results are often ill-equipped personal portals that, in the long run, fail to be truly useful.

The goal of any online personal service and support portal is to enhance the customer experience and add value. Unfortunately, as many manufacturing equipment suppliers rush to jump on the me-too portal bandwagon, the results are often ill-equipped personal portals that, in the long run, fail to be truly useful.

Cybersecurity and Data Access for Profitability Through Digitized Machine Tools

The Industrial Internet of Things (IIoT) makes it possible for manufacturers to measure and analyze the performance of their machine tools so they can boost their productivity and profitability. As the supply-chain disruptions of the global pandemic demonstrated, the ability to work remotely, understand machine behavior and use these two aspects of digitization to maintain throughput offers huge advantages for decision making and business continuity. But these advantages require data connectivity, which in turn demands cybersecurity to protect against loss, corruption or espionage.

The Industrial Internet of Things (IIoT) makes it possible for manufacturers to measure and analyze the performance of their machine tools so they can boost their productivity and profitability. As the supply-chain disruptions of the global pandemic demonstrated, the ability to work remotely, understand machine behavior and use these two aspects of digitization to maintain throughput offers huge advantages for decision making and business continuity. But these advantages require data connectivity, which in turn demands cybersecurity to protect against loss, corruption or espionage.

Business Health Check: 7 Questions To Ask Yourself

_1.png) “When should my company make capital investments?” “What solution can I integrate that will make the biggest impact on my bottom line?” “How do I know when to go on the offense and when to hold back?” These are the tough business strategy questions that shop owners and leaders have to ask every day. And there are few better times to pause and take stock of how your business is doing than now, as the first quarter of 2021 draws to a close.

“When should my company make capital investments?” “What solution can I integrate that will make the biggest impact on my bottom line?” “How do I know when to go on the offense and when to hold back?” These are the tough business strategy questions that shop owners and leaders have to ask every day. And there are few better times to pause and take stock of how your business is doing than now, as the first quarter of 2021 draws to a close.

Explore Mazak – Now Anytime, Anywhere

At this point, saying that the last year has been “challenging” is a cliché – and an understatement. No matter the industry, no matter the region, manufacturing hasn’t seen a disruption like this in generations. However, as has often been the case with our industry, we meet tough times head on with innovation and grit. Like you, Mazak has developed new ways to stay close to our customers, and now, we’re more accessible than ever before thanks to Mazak Interactive.

At this point, saying that the last year has been “challenging” is a cliché – and an understatement. No matter the industry, no matter the region, manufacturing hasn’t seen a disruption like this in generations. However, as has often been the case with our industry, we meet tough times head on with innovation and grit. Like you, Mazak has developed new ways to stay close to our customers, and now, we’re more accessible than ever before thanks to Mazak Interactive.

Making Manufacturing Ez: Four Ways Mazak Made the Ez Series Our Most Accessible Machines Ever

During the December All Axes LIVE event, Mazak premiered the new Ez Series – QT-Ez CNC Turning Centers, VC-Ez Vertical Machining Centers and MAZATROL SmoothEz CNCs. Attendees experienced just how capable and affordable these machines can be. Designed and manufactured in Florence, Kentucky, the Ez Series delivers Mazak quality, reliability and performance that can be easily integrated into any job shop. Ergonomic and optimized, these are the most affordable Mazaks yet.

During the December All Axes LIVE event, Mazak premiered the new Ez Series – QT-Ez CNC Turning Centers, VC-Ez Vertical Machining Centers and MAZATROL SmoothEz CNCs. Attendees experienced just how capable and affordable these machines can be. Designed and manufactured in Florence, Kentucky, the Ez Series delivers Mazak quality, reliability and performance that can be easily integrated into any job shop. Ergonomic and optimized, these are the most affordable Mazaks yet.

Mazak Brings Our Factory to You With the 360° Virtual Campus Tour

Since the 1970s, Mazak has manufactured advanced machining technology at our Florence, Kentucky-based campus here in the heartlands. Through the years, our U.S. headquarters has become one of the most technologically sophisticated manufacturing facilities in the world – and the hub of a global network of Technology and Technical Centers that gives customers access to Mazak’s world-class service and support. And now, through our 360º Virtual Campus Tour, it’s easier than ever for you to see how the team at Mazak uses our infrastructure to support your shop.

Since the 1970s, Mazak has manufactured advanced machining technology at our Florence, Kentucky-based campus here in the heartlands. Through the years, our U.S. headquarters has become one of the most technologically sophisticated manufacturing facilities in the world – and the hub of a global network of Technology and Technical Centers that gives customers access to Mazak’s world-class service and support. And now, through our 360º Virtual Campus Tour, it’s easier than ever for you to see how the team at Mazak uses our infrastructure to support your shop.

Digital Twins Add Certainty to Production Processes

In manufacturing, the accuracy of every cut depends on using the correct tool and entering the proper data for it. Human intervention adds uncertainty to machining processes with every manual entry of setup information. That uncertainty disappears, however, when software enables digital twins to enter the picture through direct CAM system integration, enabling shops to program parts offline with access to all the details of real-time machine setups and optimization.

In manufacturing, the accuracy of every cut depends on using the correct tool and entering the proper data for it. Human intervention adds uncertainty to machining processes with every manual entry of setup information. That uncertainty disappears, however, when software enables digital twins to enter the picture through direct CAM system integration, enabling shops to program parts offline with access to all the details of real-time machine setups and optimization.

With Automation Comes Agility

Every month in 2020 has required another round of reinventing how shops do business – but in the fast-paced world of manufacturing, this isn’t anything new. Technological advancements, product innovations, scientific breakthroughs and shifting supply chains are among a few of the reasons why manufacturers must constantly improve to keep ahead of the competition, especially when the competitive landscape now spans the entire globe. Flexibility is more crucial than ever before, and many shops are discovering a simple fact: with automation comes agility.

Every month in 2020 has required another round of reinventing how shops do business – but in the fast-paced world of manufacturing, this isn’t anything new. Technological advancements, product innovations, scientific breakthroughs and shifting supply chains are among a few of the reasons why manufacturers must constantly improve to keep ahead of the competition, especially when the competitive landscape now spans the entire globe. Flexibility is more crucial than ever before, and many shops are discovering a simple fact: with automation comes agility.

Mazak Delivers Progressive Learning Directly to Your Shop

A well-trained team is crucial for manufacturing success. That’s why Mazak has long offered a Progressive Learning program with hands-on training for all of our equipment at Technology and Technical Centers across North America. However, as with most aspects of life in 2020, COVID-19 has changed the way we approach training at Mazak – and with the help of advanced technology, we’ve made it more accessible than ever, with remote learning opportunities that have been so popular that they’ll remain a staple of our educational programs going forward.

A well-trained team is crucial for manufacturing success. That’s why Mazak has long offered a Progressive Learning program with hands-on training for all of our equipment at Technology and Technical Centers across North America. However, as with most aspects of life in 2020, COVID-19 has changed the way we approach training at Mazak – and with the help of advanced technology, we’ve made it more accessible than ever, with remote learning opportunities that have been so popular that they’ll remain a staple of our educational programs going forward.

Pandemic Creates New Job Roles and Fosters Automation Investment

“Those who cannot remember the past are condemned to repeat it.” This observation was made by philosopher George Santayana in 1905, but can help manufacturers today avoid mistakes in responding to the impacts of the pandemic. History shows that there are two likely outcomes of the current crisis which relate to manufacturing.

“Those who cannot remember the past are condemned to repeat it.” This observation was made by philosopher George Santayana in 1905, but can help manufacturers today avoid mistakes in responding to the impacts of the pandemic. History shows that there are two likely outcomes of the current crisis which relate to manufacturing.

Fabricating a COVID-19 Solution the Mazak Way

At Mazak, we’re proud to manufacture some of the best machine tools in the world at our North American Headquarters in Florence, Kentucky, from cost-effective turning machines to the most advanced HYBRID Multi-Tasking systems. A big part of this is our Fabrication Department, which leverages powerful laser processing equipment, an experienced team of welders and an automated powder-painting process to create the enclosures for all our machines.

At Mazak, we’re proud to manufacture some of the best machine tools in the world at our North American Headquarters in Florence, Kentucky, from cost-effective turning machines to the most advanced HYBRID Multi-Tasking systems. A big part of this is our Fabrication Department, which leverages powerful laser processing equipment, an experienced team of welders and an automated powder-painting process to create the enclosures for all our machines.

A Smoother Way to Manage Part Programs in the Digital Age

Since the dawn of computer science more than two centuries ago, one thing has remained constant: Programming and data entry are tougher than they look. From the first computers’ punch cards to today’s programming languages, a single, minor error can mean the difference between a functional program and a crashed computer. And when a buggy program is run on a CNC machine tool, it likely won’t just be the computer that crashes.

Since the dawn of computer science more than two centuries ago, one thing has remained constant: Programming and data entry are tougher than they look. From the first computers’ punch cards to today’s programming languages, a single, minor error can mean the difference between a functional program and a crashed computer. And when a buggy program is run on a CNC machine tool, it likely won’t just be the computer that crashes.

Now More Than Ever, Technology and Innovation Will Keep Manufacturers Competitive

Manufacturing has always been defined by relentless innovation. Across industries and around the world, shops have pursued cutting-edge technologies to maintain a competitive advantage, from the rise of NC and CNC machining to today’s fully interconnected and online facilities. And in response to the pressing issues of our time, such as the widening skills gap or the rise of mass customization, OEMs like Mazak have sought to provide state-of-the-art solutions that make it possible for operators to be more productive than ever before.

Manufacturing has always been defined by relentless innovation. Across industries and around the world, shops have pursued cutting-edge technologies to maintain a competitive advantage, from the rise of NC and CNC machining to today’s fully interconnected and online facilities. And in response to the pressing issues of our time, such as the widening skills gap or the rise of mass customization, OEMs like Mazak have sought to provide state-of-the-art solutions that make it possible for operators to be more productive than ever before.

Probe Your Parts in 20 Seconds With SMOOTH Set & Inspect

As manufacturing technology has grown more and more sophisticated, the level of complexity has grown as well. Even modest machine tools today have precision that can be measured in microns – which means part and tool setup must be just as precise.

As manufacturing technology has grown more and more sophisticated, the level of complexity has grown as well. Even modest machine tools today have precision that can be measured in microns – which means part and tool setup must be just as precise.

Re-tooling Your Shop to Manage Risk in Uncertain Times

COVID-19 has been an unwelcome game changer. The global pandemic will require us to alter just about every aspect of our lives – both at home and at work. And while it may seem counterintuitive to think about a silver lining amidst this current devastating situation, there is one, according to Mazak Corporation Vice President of Sales and Marketing Chuck Birkle.

COVID-19 has been an unwelcome game changer. The global pandemic will require us to alter just about every aspect of our lives – both at home and at work. And while it may seem counterintuitive to think about a silver lining amidst this current devastating situation, there is one, according to Mazak Corporation Vice President of Sales and Marketing Chuck Birkle.

Why Multi-Tasking?

Multi-Tasking adds efficiency to every aspect of manufacturing production. Because it enables start-to-finish production of parts that require a multi-axis approach to multiple processes, it cuts production lead times and part costs by eliminating, in many cases, the need for multiple clampings and multiple machines.

Multi-Tasking adds efficiency to every aspect of manufacturing production. Because it enables start-to-finish production of parts that require a multi-axis approach to multiple processes, it cuts production lead times and part costs by eliminating, in many cases, the need for multiple clampings and multiple machines.

Reshoring Goes Viral

The COVID-19 pandemic has revealed many heroes among our neighbors, from the doctors and nurses fighting on the front lines to the grocery store and sanitation workers keeping the world running. Manufacturing, both in the medical industry and beyond, has its role to play as well, and heroes throughout the industry have been doing their part.

The COVID-19 pandemic has revealed many heroes among our neighbors, from the doctors and nurses fighting on the front lines to the grocery store and sanitation workers keeping the world running. Manufacturing, both in the medical industry and beyond, has its role to play as well, and heroes throughout the industry have been doing their part.

Lowest Life-cycle Costs vs. Lowest Price

For manufacturers overseeing major capital investments, understanding the true cost of a product or service can be difficult. This is probably why most prefer to simplify their purchasing decisions by basing it on the bottom-line price alone. While this approach theoretically makes sense – a dollar saved today is a dollar to spend on more tomorrow – it fosters a very serious problem: It fails to take into account the total cost of ownership across the full life cycle of an investment.

For manufacturers overseeing major capital investments, understanding the true cost of a product or service can be difficult. This is probably why most prefer to simplify their purchasing decisions by basing it on the bottom-line price alone. While this approach theoretically makes sense – a dollar saved today is a dollar to spend on more tomorrow – it fosters a very serious problem: It fails to take into account the total cost of ownership across the full life cycle of an investment.

Diamonds Are a Friction Stir Welder’s Best Friend for Aluminum

Modern aluminum alloys are used everywhere in world around us, from car bodies to aerospace launch vehicles and from high-speed rail cars to cruise ships. Thanks to the addition of various other metals, including copper, magnesium, silicon and zinc, among others, lightweight aluminum excels in tough environments and at high temperatures, making it perfect for increasing fuel efficiency across virtually every type of transportation.

Modern aluminum alloys are used everywhere in world around us, from car bodies to aerospace launch vehicles and from high-speed rail cars to cruise ships. Thanks to the addition of various other metals, including copper, magnesium, silicon and zinc, among others, lightweight aluminum excels in tough environments and at high temperatures, making it perfect for increasing fuel efficiency across virtually every type of transportation.

Mazak, Building Bridges to the Final Frontier

At Mazak, we’re proud to provide manufacturing technology that companies around the world use to build the products and infrastructure of the future. Our machine tools cut parts that appear on racetracks and in undersea oil wells, on airplanes overhead and wastewater systems below.

At Mazak, we’re proud to provide manufacturing technology that companies around the world use to build the products and infrastructure of the future. Our machine tools cut parts that appear on racetracks and in undersea oil wells, on airplanes overhead and wastewater systems below.

Add Better Welds to Your Workflow With Friction Stir Welding (FSW)

As a pioneer in Friction Stir Welding (FSW), Mazak MegaStir specializes in finding ways to remove challenging materials from the impossible-to-join list, creating defect-free joints with greater strength than conventional welds. Within the Mazak HYBRID Multi-Tasking family of machine tools, FSW technology often holds the key to breakthroughs in production for aerospace, electronics, energy production and shipbuilding.

As a pioneer in Friction Stir Welding (FSW), Mazak MegaStir specializes in finding ways to remove challenging materials from the impossible-to-join list, creating defect-free joints with greater strength than conventional welds. Within the Mazak HYBRID Multi-Tasking family of machine tools, FSW technology often holds the key to breakthroughs in production for aerospace, electronics, energy production and shipbuilding.

Make Work Hardening Work for You With Friction Stir Welding (FSW)

As part of the HYBRID Multi-Tasking family of machine tools, Friction Stir Welding (FSW) technology from Mazak MegaStir has already transformed numerous industries. Defect-free welds make it vital in high-tech applications such as semiconductor fabrication equipment, while the absence of filler wire significantly reduces the weight of welds for aerospace, automotive and marine applications. But despite the name, FSW can be useful for more than just welding – its frictional heat can also be used for highly precise work hardening, a technique that Mazak MegaStir investigated in an experiment butt welding dual-phase (DP) steel.

As part of the HYBRID Multi-Tasking family of machine tools, Friction Stir Welding (FSW) technology from Mazak MegaStir has already transformed numerous industries. Defect-free welds make it vital in high-tech applications such as semiconductor fabrication equipment, while the absence of filler wire significantly reduces the weight of welds for aerospace, automotive and marine applications. But despite the name, FSW can be useful for more than just welding – its frictional heat can also be used for highly precise work hardening, a technique that Mazak MegaStir investigated in an experiment butt welding dual-phase (DP) steel.

Overcoming Challenges With Mazak Digital Solutions

When discussing the role of digital technology in manufacturing, many commentators outside the industry talk about it as the future. Shop owners and manufacturers, however, know that the future is already here. In this new digital age, shops must merge advanced technology and manufacturing. They’re applying innovative solutions on the factory floor as more advanced materials and complex part features find their way into everyday products. And to help shops navigate this merger, Mazak created SMOOTH TECHNOLOGY and a full suite of Mazak digital solutions.

When discussing the role of digital technology in manufacturing, many commentators outside the industry talk about it as the future. Shop owners and manufacturers, however, know that the future is already here. In this new digital age, shops must merge advanced technology and manufacturing. They’re applying innovative solutions on the factory floor as more advanced materials and complex part features find their way into everyday products. And to help shops navigate this merger, Mazak created SMOOTH TECHNOLOGY and a full suite of Mazak digital solutions.

What You Missed at DISCOVER 2019

Visitors who joined the Mazak team at our Florence, Kentucky-based headquarters experienced the state-of-the-art technology designed to meet the challenges of modern manufacturing – and if you were unable to join us this year, you missed our biggest and best show yet. We celebrated 100 years of bringing the spirit of Together Success to our customers and partners around the world, and we had the opportunity to showcase how we’re working together with you to discover even more in the years to come.

Visitors who joined the Mazak team at our Florence, Kentucky-based headquarters experienced the state-of-the-art technology designed to meet the challenges of modern manufacturing – and if you were unable to join us this year, you missed our biggest and best show yet. We celebrated 100 years of bringing the spirit of Together Success to our customers and partners around the world, and we had the opportunity to showcase how we’re working together with you to discover even more in the years to come.

Mazak’s New Spindle Rebuild Facility: A Spindle Production Powerhouse

The spindle is the heart of a machine tool, and we know how much you depend on your machine’s spindle performance to meet your overall production and business goals. At Mazak, we build and repair spindles better than anyone else. So, expanding our already industry-leading Spindle Rebuild Department to make it a spindle production powerhouse is one of our top priorities. The new facility is currently under construction on Mazak’s Kentucky campus. Once it’s complete, we’ll be able to get you the spindles you need faster than ever before, minimizing downtime and helping your shop stay productive and profitable.

The spindle is the heart of a machine tool, and we know how much you depend on your machine’s spindle performance to meet your overall production and business goals. At Mazak, we build and repair spindles better than anyone else. So, expanding our already industry-leading Spindle Rebuild Department to make it a spindle production powerhouse is one of our top priorities. The new facility is currently under construction on Mazak’s Kentucky campus. Once it’s complete, we’ll be able to get you the spindles you need faster than ever before, minimizing downtime and helping your shop stay productive and profitable.

Key Technological Breakthroughs Advanced Multi-Tasking

Today, when many people think of Multi-Tasking, they think of INTEGREX, the series of Mazak machines that introduced the concept to many manufacturers, and the myriad benefits shops can achieve with the technology. Without the need to transfer workpieces from one machine to the next, Multi-Tasking machines require minimal human intervention and can operate unattended for longer periods of time. They allow manufacturers to accomplish more with fewer machine tools on their factory floors, which saves valuable production space. Fewer required machines, in turn, results in lower production costs and shorter job turnaround times.

Today, when many people think of Multi-Tasking, they think of INTEGREX, the series of Mazak machines that introduced the concept to many manufacturers, and the myriad benefits shops can achieve with the technology. Without the need to transfer workpieces from one machine to the next, Multi-Tasking machines require minimal human intervention and can operate unattended for longer periods of time. They allow manufacturers to accomplish more with fewer machine tools on their factory floors, which saves valuable production space. Fewer required machines, in turn, results in lower production costs and shorter job turnaround times.

Why It’s Important to DISCOVER What We Can Do Together

November will soon arrive, and the team here at Mazak is excited to show all of our customers what we’ve been working on for DISCOVER 2019. Our theme for this year’s version of the industry’s largest private event is “Discover What We Can Do Together,” because our customers’ success is our success, and each of our successes advance our entire industry. Regardless of the size of a manufacturer’s shop, our primary goal is to help them discover the resources they need to be as productive and profitable as they can be – and at DISCOVER 2019, you will have the opportunity to see that firsthand.

November will soon arrive, and the team here at Mazak is excited to show all of our customers what we’ve been working on for DISCOVER 2019. Our theme for this year’s version of the industry’s largest private event is “Discover What We Can Do Together,” because our customers’ success is our success, and each of our successes advance our entire industry. Regardless of the size of a manufacturer’s shop, our primary goal is to help them discover the resources they need to be as productive and profitable as they can be – and at DISCOVER 2019, you will have the opportunity to see that firsthand.

Dynamics 365 Field Service Means Faster, Better Service

To simplify the service experience for customers and service professionals alike, Mazak Corporation has introduced Dynamics 365 (D365) Field Service, an electronic service management system. Designed to speed up the process and get your manufacturing equipment back up and running as fast as possible, D365 eliminates paper reports and manual follow-up calls in favor of an automated system made for easy, fast and effective communication.

To simplify the service experience for customers and service professionals alike, Mazak Corporation has introduced Dynamics 365 (D365) Field Service, an electronic service management system. Designed to speed up the process and get your manufacturing equipment back up and running as fast as possible, D365 eliminates paper reports and manual follow-up calls in favor of an automated system made for easy, fast and effective communication.

Mazak Employees Meet and Mingle with Team Penske Drivers

In recognition of the continued hard work and dedication of all its employees, Mazak Corporation recently hosted an employee appreciation event with special guests Team Penske drivers Brad Keselowski #2 Ford Mustang (MENCS)/Ford Mustang (NXS) and Austin Cindric #22 Mazak Ford Mustang (NXS).

In recognition of the continued hard work and dedication of all its employees, Mazak Corporation recently hosted an employee appreciation event with special guests Team Penske drivers Brad Keselowski #2 Ford Mustang (MENCS)/Ford Mustang (NXS) and Austin Cindric #22 Mazak Ford Mustang (NXS).

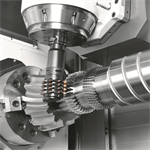

Machine Gears With Ease Thanks to HYBRID Multi-Tasking

Many shops shy away from manufacturing jobs involving parts that require some form of gear machining operations. These shops believe that such work is very complicated and requires specialized expertise and equipment, including individual machines dedicated to gear skiving or hobbing. But instead of refusing gear work or farming it out to gear specialists, job shops can easily keep gear work in-house – and even attract new customers – with the power of the INTEGREX Auto Gear (AG) series.

Many shops shy away from manufacturing jobs involving parts that require some form of gear machining operations. These shops believe that such work is very complicated and requires specialized expertise and equipment, including individual machines dedicated to gear skiving or hobbing. But instead of refusing gear work or farming it out to gear specialists, job shops can easily keep gear work in-house – and even attract new customers – with the power of the INTEGREX Auto Gear (AG) series.

Defusing Explosive Titanium Additive Situations

For manufacturers across every industry, additive manufacturing (AM) holds enormous promise, particularly when it comes to the production of parts made from high-value materials such as titanium. Rather than starting with a block of titanium large enough to contain an entire part and cutting it down to size – creating a massive heap of chips in the process – AM allows manufacturers to build parts to near-net shape. Nevertheless, one key feature shared by many AM processes presents a serious challenge to the technique’s widespread use: the volatility of titanium feedstock.

For manufacturers across every industry, additive manufacturing (AM) holds enormous promise, particularly when it comes to the production of parts made from high-value materials such as titanium. Rather than starting with a block of titanium large enough to contain an entire part and cutting it down to size – creating a massive heap of chips in the process – AM allows manufacturers to build parts to near-net shape. Nevertheless, one key feature shared by many AM processes presents a serious challenge to the technique’s widespread use: the volatility of titanium feedstock.

Climb the Levels of Multi-Tasking with QUICK TURN

Ever since the creation of the first all-metal lathe in 1751, manufacturers have depended on highly flexible and precise “mother machines,” the metalcutting equipment used to produce all other factory equipment. More than 200 years later, Mazak contributed to this effort with its SLANT TURN 40 ATC Mill Center, which gave manufacturers the ability to mill and turn on a single machine platform. Today, Mazak offers a comprehensive range of solutions – the Five Levels of Multi-Tasking – designed to ensure that each shop has an option that suits its unique needs.

Ever since the creation of the first all-metal lathe in 1751, manufacturers have depended on highly flexible and precise “mother machines,” the metalcutting equipment used to produce all other factory equipment. More than 200 years later, Mazak contributed to this effort with its SLANT TURN 40 ATC Mill Center, which gave manufacturers the ability to mill and turn on a single machine platform. Today, Mazak offers a comprehensive range of solutions – the Five Levels of Multi-Tasking – designed to ensure that each shop has an option that suits its unique needs.

Mazak Technology Centers Are There For Your Manufacturing Success

Across Canada, the United States and in Mexico, our network of Mazak Technology Centers puts our customers first so they can take fully productive, profitable advantage of their investments in Mazak manufacturing technology.

Read MoreTechnology Plus Innovation Equals Productivity for Mazak

Mazak recently received the prestigious Top Plant Award from Plant Engineering magazine. The award recognized all that we've accomplished at our Florence, Kentucky, plant, and I’d like to take this time to share what we've done.

Mazak recently received the prestigious Top Plant Award from Plant Engineering magazine. The award recognized all that we've accomplished at our Florence, Kentucky, plant, and I’d like to take this time to share what we've done.

This Spring, Mazak Meets Innovation in San Francisco

Mazak Corporation has long been dedicated to supporting the growth of high-tech innovation and manufacturing excellence on the West Coast, including offices mere miles from the heart of Silicon Valley in Milpitas, California. And this year, the company will demonstrate its continued commitment to the region and its diverse industries – including semiconductor fabrication, aerospace, medical devices, construction, agriculture and more – with the grand opening of a new 10,000-square-foot San Francisco Technical Center in nearby Fremont.

Read MoreBridging the Skills Gap with MAZATROL

Mazak has spent decades perfecting its human-machine interfaces (HMI), seeking at every opportunity to simplify the operation of our machines and streamline the learning process for new operators. This effort has included everything from new machine controls to the Progressive Learning program we offer at Technology and Technical Centers across North America. Perhaps the most important element of our mission to fill the skills gap, however, is MAZATROL, the industry’s leading conversational programming language for CNC machining.

Read MoreArtificial Intelligence Makes Spindle Health Monitoring a Reality

Spindle downtime costs money in more ways than one. The failure of a single machine can take down an entire cell or disable a multi-machine production process. Downtime also can lead to a pattern of missed commitments that harms supplier/customer relationships. But without the ability to analyze spindle behavior and predict approaching failures, shops can find themselves in the middle of large, deadline-sensitive jobs with out-of-commission equipment, waiting for replacement parts that could take weeks to arrive. Rather than compromise profitability, shops need a maintenance program that anticipates problems – and new digital monitoring technologies can help screen out these avoidable setbacks.

Read MoreMazak Further Expands Processing Flexibility With HYBRID FSW

Some of the biggest challenges in manufacturing involve joining pieces of metal without altering their microstructure, creating substantial heat-affected zones, applying filler material or making the metal porous, especially where vastly different shapes and dissimilar metals come together. As Mazak continues to advance the flexible talents of its HYBRID Multi-Tasking machines, one of the newest – and most innovative – of these capabilities lies in friction stir welding (FSW), a technology that addresses these joining challenges with new approaches that weren't readily available just a few years ago. Best of all, Mazak combines FSW technology – which produces better welds than conventional methods – with conventional part machining capabilities for complete part processing on one highly productive multi-tasking platform.

Some of the biggest challenges in manufacturing involve joining pieces of metal without altering their microstructure, creating substantial heat-affected zones, applying filler material or making the metal porous, especially where vastly different shapes and dissimilar metals come together. As Mazak continues to advance the flexible talents of its HYBRID Multi-Tasking machines, one of the newest – and most innovative – of these capabilities lies in friction stir welding (FSW), a technology that addresses these joining challenges with new approaches that weren't readily available just a few years ago. Best of all, Mazak combines FSW technology – which produces better welds than conventional methods – with conventional part machining capabilities for complete part processing on one highly productive multi-tasking platform.

Multi-Tasking: What Is It Good For? Absolutely Everything!

Multi-Tasking machine tool technology has revolutionized manufacturing and continues to play a critical role in today’s truly progressive shops. Besides the amazing gains in productivity, Multi-Tasking technology has catapulted shops, especially smaller ones, to levels where they can easily machine the most complex parts in the world and do so cost-effectively.

Read MoreMulti-Tasking Facts and Fiction

Despite the fact that Multi-Tasking technology has become increasingly common in shops across the country and around the world, many manufacturers still believe such machines are costly and a challenge to integrate into existing processes and automation. Where these myths arose remains a mystery, but the facts are easy to find, especially when discussing Mazak Multi-Tasking. Here are a few myths we can quickly debunk.

Read MoreThe Best of Both Programming Worlds Optimize Metalcutting

Truly effective controls allow for programming everything from simple to complex part geometries either in the front office or on the shop floor at the machine tool. These advanced controls offer the best of both worlds – G-code (EIA/ISO) programming as well as conversational type part programming. Mazak’s MAZATROL Smooth CNCs are just that type of advanced machine control.

Read MoreDiscover Automation with Mazak Event Draws Much Attention

The recently held Mazak Canada Discover Automation with Mazak event drew much attention from regional manufacturers, area students and the media, so much so that a third day was added. During the event from November 8-9, Mazak Canada provided live demonstrations of machine and robotic automation and showed how it can truly benefit manufacturing production and overall productivity. It also hosted an appreciation night for VIP guests, including members of the Canadian Tooling Manufacturing Association and the Society of Manufacturing Engineers.

The recently held Mazak Canada Discover Automation with Mazak event drew much attention from regional manufacturers, area students and the media, so much so that a third day was added. During the event from November 8-9, Mazak Canada provided live demonstrations of machine and robotic automation and showed how it can truly benefit manufacturing production and overall productivity. It also hosted an appreciation night for VIP guests, including members of the Canadian Tooling Manufacturing Association and the Society of Manufacturing Engineers.

Beat the Manufacturing Clock With Multi-Tasking

The reduction of long lead times won’t be achieved by simply reducing machining cycle times; shaving seconds off a part’s in-cut time is nothing compared to eliminating entire steps in the process, especially time-consuming tasks that require manual intervention. That’s why manufacturers turn to Mazak and our innovative Multi-Tasking machines, which bring multiple machining processes into one machine platform to achieve single-setup manufacturing.

Read MoreAfter IMTS, Together Success Continues

At IMTS 2018, a simple invitation hung over Mazak's booth: “Discover what we can do together.” And now that another fantastic show has unfolded at Chicago’s McCormick Place, we’re excited to talk about what we’ll discover together next.

Read MoreDiscover More With Mazak: See Us at IMTS 2018

Once again, it’s time for the manufacturing world to converge on Chicago for IMTS, North America’s largest trade show. Mazak's presence at IMTS 2018 includes so much advanced technology, we need two booths to showcase it. Along with Booth #338300 in the South Hall, you'll also find us in Booth #432000 in the West Hall.

Read MoreCost-Effective Automation Adds Real Productivity to Your Bottom Line

Automation's benefits for your shop extend beyond increased spindle utilization and higher output for people and machines. Along with those production advantages, automation also yields improved part accuracy and consistency for better process control, reduces the potential for human error and enables you to schedule lights out production.

Read MoreMazak Chairman Brian Papke Inducted into the Northern Kentucky Business Hall of Fame

At a gala event held at the Covington, Kentucky-based Metropolitan Club in late April, the Northern Kentucky Chamber of Commerce and NKY Magazine inducted Mazak Chairman Brian Papke into the Northern Kentucky Business Hall of Fame. The award honors men and women who have made a lasting contribution to the community in economic, cultural and civic endeavors.

Read MoreHYBRID Multi-Tasking Redefines Manufacturing with New Technologies

Forget everything you thought you knew about manufacturing, because Mazak’s HYBRID technology promises to change it all and take you beyond conventional multi-process machine tools into the real future of Multi-Tasking.

Read MoreTeam Penske’s Cindric Cinches Top 10 Finish in Mazak Car

When Roger Penske reopened the doors to his NASCAR racing organization in 1991, Mazak served as one of the team’s first technical sponsors. Today, Team Penske dominates INDYCAR, NASCAR and sports car racing, and its engineers depend more than ever on Mazak’s exceptional Multi-Tasking solutions to create parts for its championship racecars.

Read MoreLooking Forward to the Next 100 Years of Discovering More with Mazak

When standing on the floor of the Mazak iSMART Factory™ in Florence, Kentucky, surrounded by the state-of-the-art technology manufacturers now work with every day, it's easy to forget that nearly a century ago, Sadakichi Yamazaki founded Yamazaki Machinery as a company focused on machines to weave straw mats. Less than a decade later, the company began producing its first machine tools, and by 1963, it had officially created the brand that remains synonymous with innovation and quality to this day. And 50 years ago, in 1968, Mazak Corporation arrived in North America, where it continues to flourish.

Read MoreLooking Forward to the Next 100 Years of Discovering More with Mazak

When standing on the floor of the Mazak iSMART Factory™ in Florence, Kentucky, surrounded by the state-of-the-art technology manufacturers now work with every day, it's easy to forget that nearly a century ago, Sadakichi Yamazaki founded Yamazaki Machinery as a company focused on machines to weave straw mats. Less than a decade later, the company began producing its first machine tools, and by 1963, it had officially created the brand that remains synonymous with innovation and quality to this day. And 50 years ago, in 1968, Mazak Corporation arrived in North America, where it continues to flourish.

Read MoreTurn to Your Spindle’s Maker for Repair and Rebuild Services

Machine spindle performance is vital to your shop’s success. When your spindles are up and running, you are making parts and money. So, what will you do if one of your spindle units requires repair or a scheduled rebuild?

Read MoreTeam Penske's Brad Keselowski Wows PRI with "Winning the Manufacturing Race"

Attendees at the Performance Racing Industry (PRI) 2017 trade show needed no introduction to Brad Keselowski, a seven-year veteran of Team Penske with two championships and dozens of victories. But they almost certainly learned something new about Keselowski: thanks to a lifetime spent in the racing industry, he has developed a real passion for manufacturing. And thanks to Team Penske's technical sponsor, Mazak, the audience at PRI 2017 got a chance to share in Keselowski's first-hand experience in the form of his talk, "Winning the Manufacturing Race."

Read MoreOvercome the Large-Part Production Challenge

If you currently manufacture large parts or are considering the addition of large-part machining capabilities to your shop, you know the distinct challenges this type of work presents. The parts are heavy, cumbersome and require close machining tolerances.

Read MoreCybersecurity: Why You Need More Than Just a Firewall

One of the biggest problems facing manufacturing today is the practice of indiscriminate internetworking. To take advantage of IT/OT integration and the Industrial Internet of Things (IIoT), some manufacturers continue to connect networks together with limited regard to security and the false assumption that minimal security is enough to ward off a cyber attack.

Read MoreMazak Hosts Students for “Making it Real–Girls & Manufacturing” Event

From last year’s box-office success, Hidden Figures, to the recent unveiling of the Women of NASA Lego® figures, girls are finding more encouragement to pursue STEM careers. Recently, Mazak had the opportunity to help inspire approximately 150 female students from local schools to learn more about manufacturing by opening our factory doors as a featured host of this year’s “Making it Real–Girls & Manufacturing” Program.

Read MoreSmall But Mighty Site Section Just for Job Shops

Have you checked out the new section of the Mazak website just for job shops? If not, you should. We promise it will be worth your while.

Read MoreContinuous Innovation Gets Service Parts to You in Record Time

Every minute your machine is down is lost productivity, and Mazak knows this, which is why we continually work to incorporate special systems, software and processes into our service parts operations to be the best we can be.

Read MoreThe Digitally Connected Factory

The digitally connected factory is rapidly becoming a reality, thanks to huge leaps in affordable data handling capabilities. As more machines begin to communicate with each other, production efficiency goes up. Add the ability of analytic tools to predict maintenance needs, and productivity improves even more.

Read MoreLet's Race - Our CNC vs Yours

SMOOTH TECHNOLOGY has revolutionized the way our machine tools perform. Spanning the entire part production landscape — from programming and metal removal to automation and data collection — this all-encompassing platform seamlessly brings unmatched speed, accuracy, functionality and ergonomics to virtually every type of metalworking application. That’s why we created the Mazak SMOOTH CHALLENGE.

Read MoreStudents Bring Their Best to Precision Machining Competition

In May, we had the honor to host the 26th annual 2017 Precision Machining Competition for Illinois high school students at our Midwest Technology Center in Schaumburg, Illinois. This competition recognizes excellence in precision machining skills and encourages students to pursue careers in manufacturing by reaching them at a critical time during their K-12 education.

Read MoreIIoT is a Journey, Not a Destination

The Internet of Things (IoT) is not a fad. Research provider BI Intelligence predicts the number of IoT devices connected to the Internet will more than triple by 2020, from 10 billion to 34 billion. Networking computers, devices and machines to collect and share data is transforming many industries, including manufacturing where it can help lower operating costs, decrease machine downtime and increase overall productivity.

Read MoreFrom Mazak to You in Seven Steps

Few, if any, machine tool OEMs can claim that 97% of parts orders ship the same day they are received. Mazak is one that can and does because we understand that every minute you have to wait is potentially lost production time.

Read MoreTwo Turrets, Two Spindles, Two Approaches

Mazak has many options when it comes to turning centers with Multi-Tasking capabilities. Two such machine series, Mazak’s MULTIPLEX Series and HQR Series, accomplish this in different ways.

Read MoreBuy It Right: What to Consider Before the Purchase of a New Machine

A new machine tool is a big investment. Make sure you carefully evaluate your needs and identify which product will help you meet your objectives. You’ll need to carefully consider your exact production goals as well as the part/jobs involved.

Read MoreGet to Know Your VC-500 AM: Maintenance Tips and Tricks

Ultra-versatile HYBRID Multi-Tasking machines, such as Mazak’s VC-500 AM, are designed for easy maintenance, but present some special maintenance requirements due to their combination of additive and subtractive technologies.

Read MoreTake Advantage of our Technology Centers to Increase Efficiency and Utilization

Manufacturing today is fast-paced – every minute of production affects the bottom line. To be competitive shops must achieve efficient use of leading edge technology backed by comprehensive service and support that ensures machines are performing at their best. Operators must also be well-trained so that they can optimize each machine’s capabilities.

Read MoreHow to Troubleshoot 11 Common MTConnect Issues

MTConnect® can help you significantly boost manufacturing efficiency and productivity by enabling your manufacturing equipment to provide valuable data in a format that is useable by data management applications. However, as with any computer-based system, issues such as missing or erroneous inputs and commands can arise and negatively affect system performance. Fortunately, MTConnect implementation issues are generally easy to recognize and resolve.

Read MoreAutomotive Shops: How to Drive Success

Shops throughout the automotive industry face many common challenges from part quality and cost reduction to the most critical factor – on time delivery. While the challenges are the same, the approaches to manufacturing and part machining can differ greatly from one tier to the next.

Read MoreWhat to Consider When Choosing Either a Single-process or Multi-Tasking Machine

Most shops today have some level of Multi-Tasking capabilities, one machining center that combines several cutting processes to reduce job setup time, increase capacity, improve machining accuracy and conserve valuable shop floor space. But is it always best to use a Multi-Tasking machine, or are there times when using a milling machine and/or separate turning machine is a better option? Here are five things to consider when making the choice:

Read MoreHow Mazak Combines Simplicity and Innovation with Value

One size does not fit all when it comes to shops and their machine tool needs. That’s why Mazak offers such a diverse line of technology, including those machining systems that are extremely cost effective without sacrificing performance. But how is this accomplished? The designs and features of Mazak’s simple but innovative QTU series of CNC Turning Centers and the VCU series of Vertical Machining Centers offer the answer to that question.

Read MoreKeep Production in Motion with Fast, Reliable Spindle Repairs

Many of your shop’s production capabilities revolve around your machine’s spindle performance, and the best way to keep your machine producing at its maximum capacity is through regular care and maintenance of this critical component. Keeping the spindle clean and well lubricated are two simple steps that will minimize problems.

Read MoreSix Multi-Tasking Machine Design Advancements Important for Job Shops

Multi-Tasking machine tool technology continues to evolve and push machine capabilities that make it easier to machine the most complex parts in the world and do so cost-effectively. Read about six recent machine design advancements that are particularly important to your job shop.

Read MoreIs It Time for Your Shop to Automate?

Many automation systems on the market today are designed for larger shops. But if you are an owner of a small shop, you may be eager to make the most of your labor resources and machine capabilities with automation, too. Our new Multi Pallet Pool (MPP) single machine automation system is designed to meet your needs.

Read MoreMaking it Real – Girls & Manufacturing at Mazak

A study conducted last year by The Manufacturing Institute, APICS and Deloitte uncovered important information about women in manufacturing. While women represent 47 percent of the total U.S. labor force, they make up only 27 percent of the manufacturing workforce. This discrepancy points to huge potential for attracting female workers to help fill the estimated 2 million jobs that are expected to go unfilled in the upcoming years due to the skills gap and natural attrition due to retirement.

Read MoreWhat is SMOOTH TECHNOLOGY

At IMTS in Chicago last month, many manufacturers, media and others who visited our booth were very interested in learning more about SMOOTH TECHNOLOGY. Rightfully so because it is unique to the industry and helps keep shops of all sizes productive, efficient, competitive and at the forefront of innovation.

Read MoreMazak Empowers Thousands of Manufacturers at IMTS

IMTS gives us a great opportunity to share our latest technology advancements with thousands of manufacturers from all over the world, and this year’s show was no exception. Our booth was a premier destination for many attendees because we showcased everything manufacturers need to thrive in today’s digital, dynamic and competitive marketplace.

Read MoreEndless Possibilities with Full 5-axis Capabilities and Additive Technology in One Machine

One of the most exciting advancements in machining technology currently is the incorporation of Additive Manufacturing (AM) technologies into Multi-Tasking machines. At Mazak, we call this concept HYBRID Multi-Tasking, and its advantages are immense. HYBRID Multi-Tasking not only revolutionizes product design and reduces time to market, but it cuts R&D costs and opens many new doors for you to explore new areas of business.

Read MoreHorizontal Machining Centers with Honing Take Production to New Heights

Honing is one of the more expensive machining processes to perform, but is crucial in the production of pumps, valves and gears. Because today’s OEMs demand smoother surfaces to make automobiles and other products quieter and more reliable, finding more efficient ways to complete this high-precision process is more important than ever.

Read MoreSafety First: 5 Basic Tips for Machine Tool Operators

Today’s machine tools are powerful and produce parts faster than ever before. And, as with any powerful piece of equipment, it’s important to apply good safety practices to reduce the risk of injury. In short, respect the machine to avoid the potential for injuries sustained from moving parts, tissue damage due to contact with cold or hot machine parts, hearing loss, eye damage and stresses put on the body due to repetitive motions, excessive reaching or heaving lifting. Thankfully, modern machine tools are designed with many safety features to help reduce these hazards.

Read MoreBeyond the High-Tech Glitz, Process Efficiency and Maximized Machine Utilization Remain the Goals

As a special guest, I attended the recent Cisco Systems Inc.’s Cisco Live event held in Las Vegas that drew upwards of 30,000 technology innovators. The event focused heavily on cloud-based infrastructures as well as cloud-based applications, processing and analyzing of data and monitoring software as they relate to many industries, including manufacturing.

Read More3 Tips for Staying Compliant and Profitable in Aerospace Parts Production

The aerospace industry has been on the upswing for a few years now, and all indications are that orders for parts will continue to increase. Parts manufacturers looking to capitalize on these opportunities must implement processes and techniques that will help keep them both compliant and profitable.

Read MoreCryogenics in Manufacturing? Absolutely!

At Mazak, we continually work toward the development of new technologies and applications that expand the realm of what is possible or improve the performance of existing machines and tools. One of our latest advancements is the integration of liquid nitrogen cryogenics technology into our new VARIAXIS i-800T full 5-axis vertical machining centers.

Read MoreDecide Which 5-axis or Multi-Tasking Machine Tool is Best for You

We’re proud to offer the industry’s most advanced and comprehensive selection of 5-axis and Multi-Tasking machine configurations so that you can easily find a machine that will best meet your needs. When making a machine selection, it’s important to choose the right one.

Read MoreConsider This When Buying a New VMC

Today’s vertical machining centers (VMCs) offer a wide range of features and capabilities – from 3-, 4- and 5-axis milling and user-friendly CNC controls to a plethora of options that further increase productivity and expand part processing possibilities in terms of shape and geometry. And while all the available variations of VMCs can seem overwhelming, there are three key considerations to keep in mind that will help narrow your selection down to the one that’s perfectly matched for your applications.

Read MoreFull 5-axis or 3 + 2 Machining: Which is Right for You?

If you currently use conventional 3-axis machining, your logical part processing progression is the step up to full 5-axis or 3 + 2 machining capabilities. While both offer advantages, understanding the fundamental differences between the two is key to determining which process will best meet your specific needs.

Read More2016 Manufacturing Outlook: Automation & Digital Integration

Now is the perfect time for manufacturers of all sizes to develop strategies for incorporating automation and digital integration into their operations. Technologies that enable them to effectively do so are readily available. Production demand is up and predicted to maintain an upward trajectory, especially in the second half of the year. And, unfortunately on the downside, we must face the reality of and deal with a continuously shrinking skilled work force while still maintaining this nation’s manufacturing productivity.

Read MoreWhat CNC programming style best suits your operations?

In the most basic sense, the functionality of a CNC is to enable a machine tool to achieve automatic, precise and consistent motion control. To do this properly, the CNC requires a set of programming instructions that tells the machine how to run a part.

Read MoreSmart Manufacturing: Bridging the Digital Divide

Since the 80s, our industry has primarily focused on lean production strategies to help offset the higher cost of doing business in this country as compared with overseas. And, while finding ways to reduce operational waste is important, the lean approach can only take us so far in a world that will soon be driven by the interconnectivity of intelligent products, processes and services.

Read More2016 Manufacturing Outlook: Currency and Capital Equipment

Any manufacturer, regardless of industry segment, faces various business risks. While some risks can be internally regulated (e.g. machine failure, talent management), others arise from external factors (e.g. economic factors, government regulations) that cannot be controlled.

Read MoreEarly IIoT Adoption: Start Small. Plan Big.

Google “big data” and you’ll get well over 18 million hits. After all, it’s become a popular buzz term in manufacturing circles as it will be the key basis of competition and business growth when Industry 4.0 takes complete hold.

Read MoreThe 10 Signs of Manufacturing Intelligence

Having a high level of intelligence is critical if you want your shop to remain competitive in a continuously advancing marketplace. This doesn’t mean you need an Albert Einstein IQ of 160, you just need to understand the value of smart technology and how to best apply it in your operations, especially as the Industrial Internet of Things (IIoT) continues to steadily progress.

Read MoreReduce Scrap in as Little as 10 Minutes

If you work with expensive workpiece materials or process highly complex components, you know how important it is to get the job done right the first time — machine a part improperly and your productivity and profitability take a beating. There are, however, quantitative measures you can take to effectively manage your scrap and rework as well as improve your machine’s overall performance.

Read MoreSuccess Comes from the Ability to Adapt

The modern economy, whether it’s at the global, domestic or local level, is fast and dynamic. And to be successful these days, companies must be able to quickly adapt to market changes as well as continuously push the envelope in developing new products and services that advance beyond the competition.

Read MoreDISCOVER 2015 is a Success!

With metalworking professionals from all over North America in attendance, DISCOVER 2015 proved to be this year’s top productivity destination. Not only did the six-day technology and education event at Mazak's North American headquarters showcase the latest metalworking equipment for improved productivity, it also explored how connectivity between smart machines, software and the Internet creates an explosion of data that will drive factories of the future.

Read MoreHow to Program Your Way to Higher Productivity

Technology advances at warp speeds these days. Think back as little as 10 years ago. We couldn’t make phone calls, take pictures, shoot video, play music, watch TV or search the Internet using a highly intuitive mobile device. We had flip phones with physical keyboards that made texting a slow, painstaking process. CNC technology has evolved in a similar fashion over the past decade, giving rise to our latest MAZATROL Smooth CNCs that have revolutionized machine tool performance.

Read MoreA Simple Approach to Machine Tool Selection

With countless 5-axis and multi-tasking machines with advanced capabilities on the market today, it can be overwhelming when trying to choose the best solution for your operations. After all, you don’t want to overspend on unnecessary functions or under invest in technology that could make you more profitable in the long run.

Read MoreWhat Customers Can Expect From An ISO 9001:2008 Certified Company

For over a decade, ISO 9001:2008 certification has been a standard for quality control and has provided companies a framework to manage their businesses effectively. Ensuring the highest quality products are made available to customers, this standard is designed to create a mindset of continual improvement in companies.

Read MoreTop Five Advanced Technologies You Will Only See At DISCOVER 2015

A digital manufacturing revolution is at hand. And, at DISCOVER 2015 you can be part of it.

Read MoreConsider Multi-Tasking Machines for Gear Skiving

At IMTS 2014, Mazak showcased how larger sized 5-axis multi-tasking vertical machining centers could allow a shop to cost-effectively and quickly produce those occasional, low-volume spiral-bevel gear sets in-house. We machined a spiral bevel gear set that included a 29-tooth, 22"-diameter pinion gear and a 114-tooth, 6-ft-diameter ring gear on our INTEGREX e-1550V/10 Multi-Tasking 5-axis Machining Center. We completed the gear set in days as opposed to months and using only the one machine.

Read MoreProduct Quality Comes With A Greater Focus

Product quality, in its most basic sense, means giving customers what they want. But at Mazak, we go beyond that by being able to anticipate and quickly meet the requirements of an ever-evolving marketplace. In fact, we manufacture our machine tools to meet today’s real-time specifications, but we can also turn our manufacturing operations on a dime to meet those of tomorrow.

Read MoreLet Automation Propel Your Business Forward

Today, with skilled labor still limited, several U.S. manufacturers are closing the gap with automation. After all, with the right automation, shops can greatly improve their part processing operations and significantly reduce costs.

Read MoreShrinking the Skills Gap Through Education

As U.S. manufacturing continues to see improvement in both orders and job creation, factories face a collective problem that could put a damper on this growth: the skills gap. As more jobs become available, and as a growing number of qualified workers begin to retire from the workforce, the need for trained, qualified workers from younger generations becomes ever more necessary. And this need will not change anytime soon.

Read MorePart Processing Operations Just Got a Whole Lot Smoother