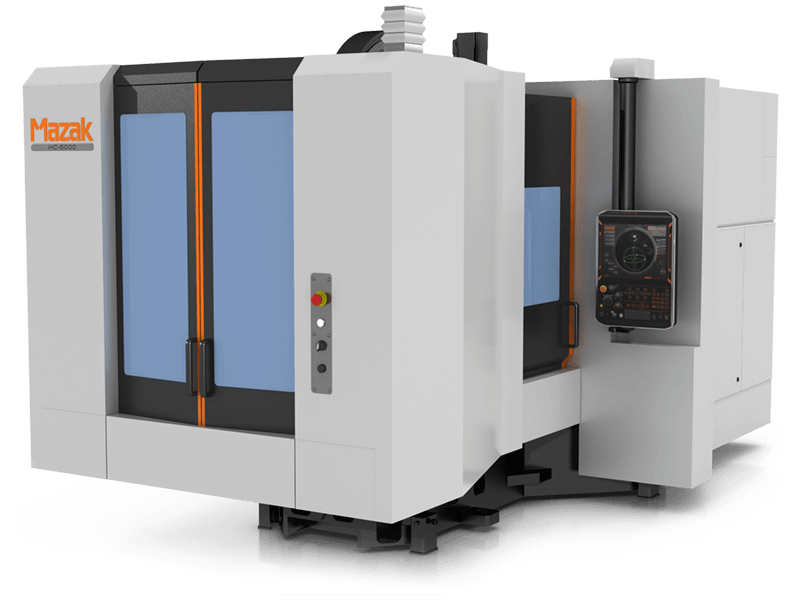

While our horizontal machining centers range in size and capacity, we design each one with quality, reliability, ease of operation and safety in mind. Furthermore, thanks to our Production-On-Demand manufacturing philosophy, all of our horizontal machining centers incorporate the latest, most advanced milling technology for boosting productivity and growing your business.

Horizontal

What is Horizontal Machining?

Horizontal Machining, also known as milling, relies on rotary cutters to remove metal from a workpiece. Horizontal machining occurs on a horizontal machining center (HMC), which employs a spindle that is parallel to the ground floor. With a horizontally oriented spindle, tools stick out of the side of the tool holder and cut across the side of a workpiece, encouraging chips to fall away from the table. Horizontal machining centers also allow for two-pallet changer integration to facilitate unattended operation and reduce part cycle times.

Why Mazak Horizontal Machining Centers?

Horizontal Machining Benefits

- Rigid designs allow for fast acceleration and increased repeatability

- Large tool storage capacities enable increased part-production versatility

- Various spindle speed and torque selections for materials ranging from aluminum to titanium

- 3-, 4- and 5-axis capabilities for infinite possibilities as to the part shapes you can process

- MX Hybrid Roller Guides provide durability and reliability for long-term accuracy

- A two-pallet changer comes standard on most models to increase spindle utilization

- On-board probing for part location and feature inspection within the cutting cycle

- User-friendly CNC controls simplify programming and increase productivity

- Configured for robot integration to facilitate unattended machining (loading/unloading)

- Integrate with our PALLETECH System for unattended “lights out” operation

A Horizontal Machining Solution for Every Application Type

Whether your application calls for heavy-duty or high-speed machining of big or small parts in a high- or low-production environment, we offer the widest range of horizontal machining centers in the industry to ensure you have the best solution for your needs with the lowest cost of ownership.

HCN Series

Wide-ranging series of machines designed to meet the diverse machining needs of numerous industries. High-rigidity construction enables high-accuracy, high-speed machining.

- Table Size: 400-500mm

- Pallet Size: 400-1250mm

- Spindle Connections: CAT 40, CAT 40/BIG PLUS, CAT 50, CAT 50/BIG PLUS, HSK-A63, HSK-A100

- Tool Capacity: 40-348 tools

- Spindles: 6k, 7k, 8k, 10k, 12k, 14k, 16k, 18k, 25k, 30k

HCR Series

High-speed and high-accuracy machining that integrates the expertise accumulated over many years in the production of simultaneous 5-axis and horizontal machining centers.

- Axes: 5

- Pallet Size: 500-630mm

- Spindle Connections: CAT 40, CAT 40/BIG PLUS, HSK-A63

- Tool Capacity: 40-348 tools

- Spindles: 12k, 18k, 25k, 30k

Contact your local Mazak Representative or visit one of our Technology Centers to identify what Mazak Machining Center best fits your part-processing needs.