Our redesigned INTEGREX i-H Series of Multi-Tasking machines takes optimized machining and easy automation to new heights. For medical manufacturers in particular, these machines meet and exceed the competitive need for precision and superior surface finishes on demanding parts that have no margin for error.

The machines within the series sport new compact footprints and require less floor space. Additionally, we’ve equipped them with faster and more powerful turning spindles, space-saving milling spindles and a new type of lower turret with live tooling capabilities. We’ve also expanded tool capacities for lower turrets and tool storage magazines, and offer a wider range of chuck size options for each machine in the series.

Because medical part production needs are constantly changing, the INTEGREX i-H Series machines allow you to retrofit various automation options in the field to accommodate those changes. Packaged as kits for fast and easy installation by Mazak service technicians, these options make it possible to purchase an INTEGREX i-H Series machine as a standard configuration, then down the road, add an overhead gantry loader, a parts unloader and parts catcher, a bar feeder, automatic chuck jaw changers for either a machine’s main or second spindles, or a pedestal-type standalone robot.

Our new magazine-style automatic jaw changers for main turning spindles, another retrofittable option for INTEGREX i-H Series machines, now is available for second spindles as well. With this capability at both spindles, the machines essentially reduce job changeovers down to the time required for the auto jaw changer to switch out for a new job. Instead of an operator taking 10 minutes or more to change over jaws on one day – and maybe 20 minutes the next – the auto changer time remains consistent, improving the predictability of your processes.

With 40% faster part loading and unloading, you can equip your INTEGREX i-H Series machine with a newly redesigned gantry loader (GL). The system is shorter in height by 16.25" (413 mm) and thus requires less overhead clearance. It provides A/B-axis swing arm synchronization, and with a conveyor at the left side of the machine, the GL further reduces load/unload time. For even greater flexibility, the new GL system can service multiple machines at once.

To further boost machine performance and provide the processing flexibility required for a wider range of medical part types, the INTEGREX i-H Series includes machine configurations with just a main turning spindle, milling spindle and tailstock, while “S” configurations feature second turning spindles and “ST”-designated machines have a second turning spindle and lower turret with live rotary tool capability. The INTEGREX i-H Series offers five bed lengths that vary from a compact 23" up to 100" (590mm to 2500mm).

Typically, the torque in second spindles is lower to instead match its speed/rpm to that of the main spindle, but INTEGREX i-H Series models’ standard main and second spindles are equal in power/torque, but we offer various horsepower/torque and bore size options for both. With equally powered main and second spindles, you can maintain the same cycle times at both spindles to perform mirror-image part processing, with one part clamped in each spindle.

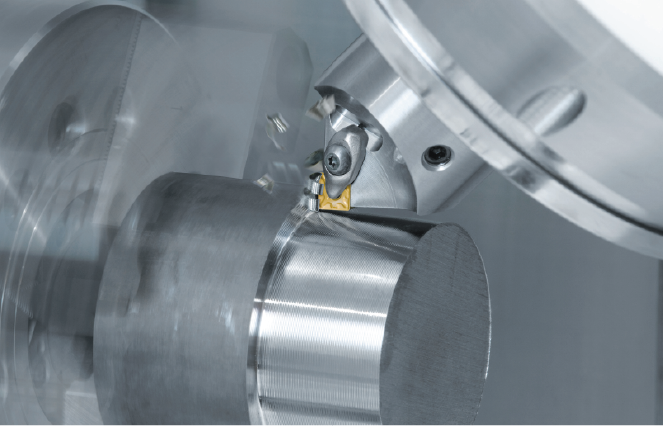

Alongside a standard slant-type lower turret, the INTEGREX i-H ST models offer a new orthogonal-type lower turret. Besides providing a faster 10,000 rpm milling spindle, expanded 12-tool capacity and improved chip accumulation control, the new turret allows shops to run larger-size parts, use longer tools and have the turret work at a machine’s main or second spindle without interference.

On the milling side, we offer INTEGREX i-H Series machines with compact milling spindles in standard, high-power and high-speed versions, as well as speeds that range from 12,000 to 20,000 rpm. For the highest level of performance, the spindles maintain their full torque ratings throughout the entire range of their spindle speeds. The totally redesigned 20,000 rpm mill spindle offers 59% higher performance output and a 4.8 second shorter acceleration time than its predecessors.

To keep pace with extended automated operations, the new INTEGREX i-H Series offers tool magazine storage capacities that can accommodate up to 112 tools. The magazines are mounted at the rear of the machine to allow for easy of automation at the front of the machine and gives shops the option to load or set up tools at either the front or rear of the machine.

All INTEGREX i-H Series machines feature our new MAZATROL SmoothAi control, which includes enhancements on the MAZATROL side and added flexibility on the EIA/ISO side, along with an optional second screen. The second monitor displays the status of multiple connected Mazaks within your shop.

With the control’s Solid MAZATROL function, you can now work from solid models to generate programs for specific part features. To further optimize machining operations, the control provides cutting-condition monitoring through its SmoothAi Spindle function and thermal stability with its Ai Thermal Shield function. The MAZATROL SmoothAi CNC also has specific functions for advanced robot automation and unmanned operations.

The new INTEGREX i-H Series of Multi-Tasking Machines from Mazak takes your medical part processing to the next level. Precision, surface finish quality, flexibility and easy automation, you get it all. Check out the whole series at www.mazakusa.com