5 Levels of Multi‑Tasking

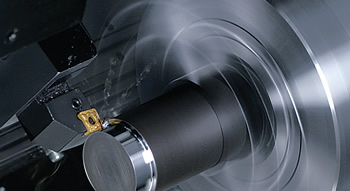

Multi-Tasking machines are extremely effective because of their ability to mill and turn part features with high accuracy and high quality, while cutting down on the number of machines required in a manufacturing facility and reducing labor cost per part.

We offer a wide and diverse selection of Multi-Tasking machines with differing capabilities. So whether you are producing small parts with unit cycle times of under a minute, or large, complex components that require a full week of machining, we have a solution to boost your efficiency, flexibility and productivity.

To ensure you have the right level of Multi-Tasking technology for your facility, we have developed 5 Levels of Multi-Tasking to fulfill your specific part machining needs.

Level 1

Machines at this level typically feature a single turning spindle and a drum-style turret with rotating tool capabilities, so you can easily achieve simple turning, milling, drilling and tapping operations.

Machines at this level typically feature a single turning spindle and a drum-style turret with rotating tool capabilities, so you can easily achieve simple turning, milling, drilling and tapping operations.

Machines at this level include:

Level 2

Machines at this level include Y-axis functionality for the machine's drum turret, which increases the range of part geometries. You can also achieve machining off the centerline and perform DONE IN ONE machining through the use of two spindles with a milling turret or two spindles with a two-turret configuration.

Machines at this level include Y-axis functionality for the machine's drum turret, which increases the range of part geometries. You can also achieve machining off the centerline and perform DONE IN ONE machining through the use of two spindles with a milling turret or two spindles with a two-turret configuration.

Machines at this level include:

Level 3

With further enhanced features, including independent milling spindle headstocks with B-axis indexing, full Y-axis travels and tooling magazines, machines at this level perform 4-axis simultaneous machining and 5-axis tool tip positioning.

With further enhanced features, including independent milling spindle headstocks with B-axis indexing, full Y-axis travels and tooling magazines, machines at this level perform 4-axis simultaneous machining and 5-axis tool tip positioning.

Machines at this level include:

Level 4

With an emphasis on automation and tackling large and highly complex parts, machines at this level allow you to achieve full, simultaneous 5-axis machining. Several machines in this category integrate with robots, while others pair perfectly with our PALLETECH System to achieve fully automated, unattended production.

With an emphasis on automation and tackling large and highly complex parts, machines at this level allow you to achieve full, simultaneous 5-axis machining. Several machines in this category integrate with robots, while others pair perfectly with our PALLETECH System to achieve fully automated, unattended production.

Machines at this level include:

Level 5

At this highly advanced level of Multi-Tasking, we equip machines from Level 4 with powerful additive and joining functions or specialized application-specific technology to create HYBRID Multi-Tasking machines. At this level, technologies like wire arc AM, friction stir welding or multi-laser metal deposition, as well as AUTO GEAR and SMOOTH Gear Cutting Solutions, enable you to machine the most demanding and complex parts in a single setup. Combine machines from this level with PALLETECH Systems or MAZATROL SMS for fully automated, unattended production.

At this highly advanced level of Multi-Tasking, we equip machines from Level 4 with powerful additive and joining functions or specialized application-specific technology to create HYBRID Multi-Tasking machines. At this level, technologies like wire arc AM, friction stir welding or multi-laser metal deposition, as well as AUTO GEAR and SMOOTH Gear Cutting Solutions, enable you to machine the most demanding and complex parts in a single setup. Combine machines from this level with PALLETECH Systems or MAZATROL SMS for fully automated, unattended production.