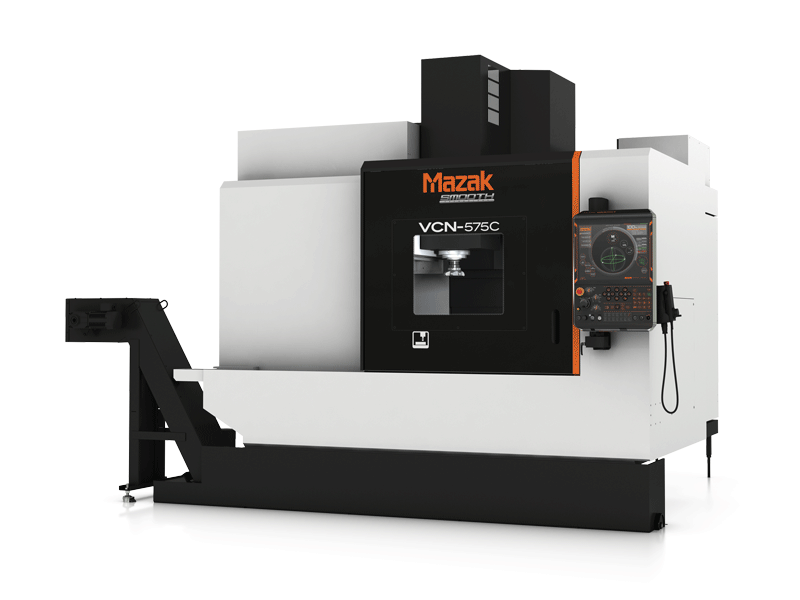

VCN-575C

MACHINE DESCRIPTION:

Made in Kentucky, the VCN-575C vertical machining center brings advanced technology, performance and value to heavy-torque machining applications. The machine features a traditional C-frame design, vibration-dampening, rigid base and headstock/column castings for extreme stability. A high-torque 50-taper spindle with maximum torque ratings give the machine the strength and power for aggressive metal removal in tough-to-machine materials. Also contributing to the machine’s productivity is an extremely fast traverse rate of 1,654 ipm in the X, Y and Z axes.

The high-speed automatic tool change system (ATC) on the VCN-575C machine is servo-driven for fast and reliable operation. Tool changes occur in 5.2 seconds to significantly reduce non-cut times and get spindles back in the cut in the shortest times possible. Such speed is possible because the ATC always takes the quickest route to the next needed tool position.

MACHINE CHARACTERISTICS:

- Standard single-table 3-axis machine (optional 4th-axis NC rotary table)

- Extremely rigid base built for stability and vibration dampening

- Robust high-performance #50 Taper spindle

- Mazak MX Hybrid Roller Guide System delivers durability, reliability and long-term accuracy

- Fast and easy conversational programming and industry standard EIA/ISO

- Standard 24-tool magazine

- Easy-to-access maintenance panel and color cables reduce maintenance time

- Optional seamless automation integration increases uptime and lights-out production

Caractéristiques de la machine

| Spécification | Values | |

|---|---|---|

| Capacité | Tableau Droite / Gauche | 1300 mm / 51.180 in |

| Tableau longitudinale | 570 mm / 22.440 in | |

| Broche | Taper broche | 50 |

| Vitesse de pointe | 6000 rpm | |

| Sortie moteur (5 Note minute) | 22 kw / 30.0 hp | |

| Magazine | Nombre d'outils | 24 |

| Nourrir axes | Voyage (axe X) | 1050 mm / 41.34 in |

| Voyage (axe Y) | 570 mm / 22.44 in | |

| Voyage (axe Z) | 510 mm / 20.08 in | |