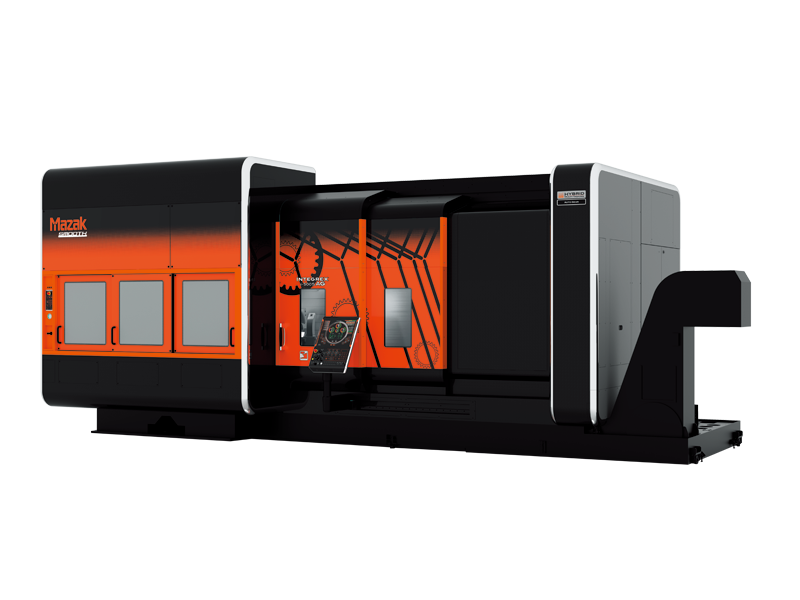

INTEGREX i-5005ST AG

Photo: INTEGREX i-5005S AG

MACHINE DESCRIPTION:

The INTEGREX i-5005ST AG HYBRID Multi-Tasking machine delivers maximum versatility and throughput. The machine combines the capabilities of a high-powered turning center and full-function machining center to produce parts in single setups, along with innovative HYBRID functionality.

This machine configuration features a second turning spindle (S) for DONE IN ONE® machining; lower turret (T), minimizing fixtures, tools, handling and non-cut time; and the HYBRID AUTO GEAR (AG) package with a full range of SMOOTH TECHNOLOGY solutions for DONE IN ONE® gear production as well.

Additionally, the machine significantly reduces lead times and improves part accuracy through the elimination of multiple setups. With full 5-axis capability, the machine easily processes fully prismatic parts from solid blocks or castings (chucked or bar fed work), round parts or sculptured parts such as aerospace components.

MACHINE CHARACTERISTICS:

- Standard 50-taper spindle for additional rigidity

- Process integration for high-accuracy machining, reduction of in-process time and initial cost

- The INTEGREX AG Series delivers maximum versatility and enhances flexibility on the production line

- Powerful turning spindle delivers heavy-duty performance

- Operators can set the tailstock position on the setup screen and move the tailstock to another position by menu-key or M-code

Caractéristiques de la machine

| Spécification | Bed Longueur - 1500U mm | |

|---|---|---|

| Capacité | Diamètre d'usinage maximum | 700 mm / 27.560 in | Usinage Longueur maximale | 1500 mm / 59.060 in |

| Broche principale | Vitesse de pointe | 2500 rpm |

| Deuxième broche | Vitesse de pointe | 2500 rpm |

| Fraisage de la broche | Axe B Voyage | 240° |

| Vitesse de pointe | 10000 rpm | |

| Nourrir axes | Voyage (axe X) | 845 mm / 33.27 in |

| Voyage (X2 Axe) | 265 mm / 10.43 in | |

| Voyage (axe Y) | 430 mm / 16.93 in | |

| Voyage (axe Z) | 1640 mm / 64.57 in | |

| Voyage (Z2 Axe) | 1373 mm / 54.06 in | |